Sky Blue Brand Light Pole provides whole solution and good after-services over nearly 29 years' development, best manufacture in China. Factory directly.

We have built our service team in India in order to give better technical support to Indian and neighboring countries.

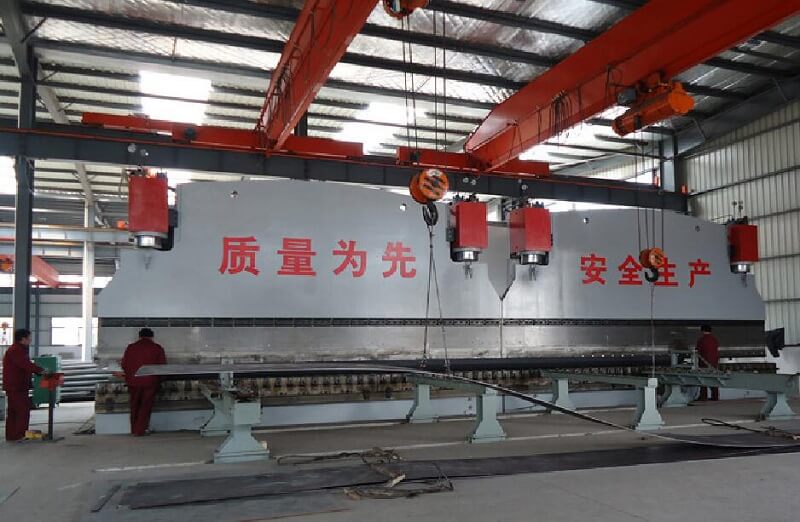

Types: Cut to length line, steel plates diagonally shearing production line, tandem press brake, automatic welding production line, steel straightened machine, tube bending machine, lamp door automatic plasma cutting machine, automatic polishing machine, electrostatic spraying production line, hole driller machine, thread rolling machine, welding machine, flame and plasma cutting machine.

Light pole height:

Generally speaking, workers need to survey and measure different environments; then select different parameters of the poles according to the brightness of the LED light source.

Application scenario: Most of the scenic spots use solar garden lights, and the height of the lamp pole is relatively low.

Light pole material:

For example, steel structures are generally used on roadsides, which have great requirements on the sturdiness of the lamp poles. However, in the scenic area, only a simple light pole is needed, because collisions and other situations will not occur in the scenic area.

Such standards are part of the industry’s rigid requirements, and part of them are accumulated by enterprises based on their many years of production experience.

Ps: So the requirement when choosing a light pole is to ensure safety.

Light poles can be divided into iron light poles, FRP light poles, cement light poles, and aluminum alloy light poles according to their materials.

The advantages of iron light pole

The disadvantages of iron light pole

The advantages of FRP light pole:

Disadvantages of FRP light poles:

Advantages of cement light pole:

Disadvantages of cement light poles:

Advantages of aluminum pole:

Disadvantages of aluminum alloy poles:

Compared to iron poles, the strength of aluminum alloy poles is relatively low, but the strength of aluminum alloy poles can reach the T6 standard through post-heat treatment.

Due to the numerous advantages of aluminum poles and other poles that are incomparable, aluminum alloy poles have been commonly used in developed countries such as Europe and America.

So, after understanding the standard, let’s see how the light pole is made!