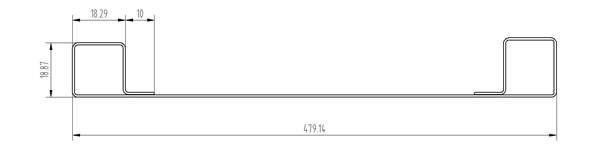

I. Profile drawing: (according to confirmation by both parties)

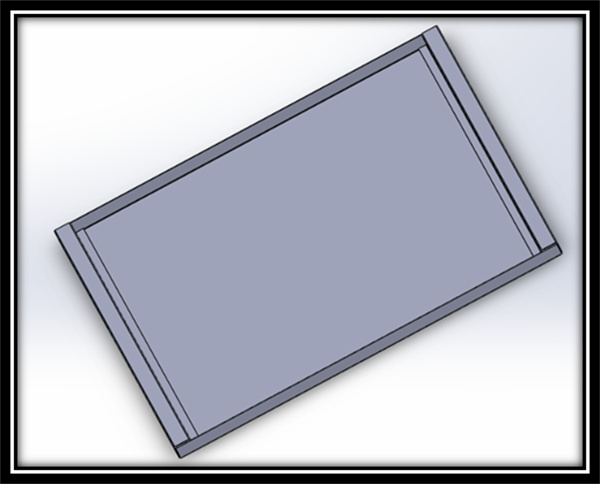

II. Overview:

· The machine can produce 400-1500mm length shelf panels.

· Effective width will be in range from 300-600mm.

· The rolling thickness of the profiles is (0.3-0.8) mm by manual adjustment.

· The production speed is 1-3 pieces/min

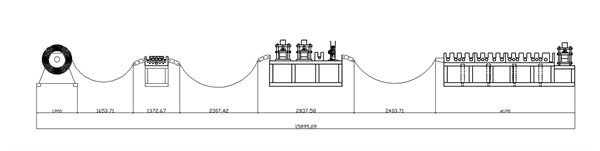

III. Process flow:

Electric Uncoiler -----> Leveling feeder -----> Punching machine --------> Roll forming ------> Roll welding machine -----> Cut off the flanging machine ------> Discharge table.

IV. Components of the Machine Line:

1. Uncoiler:

1) Passive feeding, manual tightening

2) Bearing capacity of uncoiler : 5 T

3) Inner diameter of support roll : Φ470 ± 30mm

4) Max roll width : 0-1000mm

2. Hydraulic punching machine:

1) Punching die frame:60T

2) Die material: Cr12MoV

3) Die treatment: After heat treatment HRC60-62℃

4) Leveling feeder: 5.5 KW motor , 11 roller feeding

5) The double-sided adjustable punching die includes 2 sets of Layer board piercing die

6) Each hole distance can be set for punching according to production needs

7) The servo motor : 2.2KW

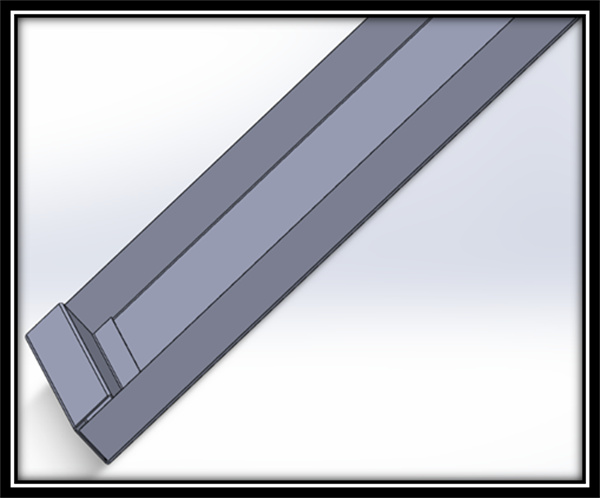

3. Roll Former:

1) The frame of the main machine adopts 100mm × 50mm × 4mm square rectangular tube and A3 carbon steel plate to be welded as a whole, and then passes through the plane of precision milling machine of planer milling machine

2) The thickness of the wall plate of the main machine is 22mm (independent gear box). The wall plate bearing holes and slider slots are processed by wire cutting in one plane. The independent gear box wall plate is fixed on one side and adjustable on the other.

3) Roll material: CR12MoV high quality die steel

4) Heat treatment: the hardness of the roller after twice vacuum tempering treatment HRC = 60-62℃

5) Roll processing: after the vacuum heat treatment of the roll, Solidworks/ Mastercam integrated technology is adopted.

6) Motor power of forming machine : 5.5 KW

7) Integration technology and CNC lathe finishing processing are adopted

8) The accuracy is within ± 0.02 mm.

9) Main machine roller inner hole fine grinding, Processing accuracy : ± 0.02mm

10) Main shaft ¢50mm,Processing accuracy : ± 0.02mm

4. Transmission part:

1) The main engine:5.5kW ,copper core motor

2) Voltage standard: 380V/50HZ/3P

3) Gear reducer: equipped with JZQ350

4) Drive the 1.2-inch 12-tooth main chain drive

5) The main machine adopts 1.0 inch 12-tooth sprocket drive

6) Bearing : HRB 6208

5. Auto change track:

1) Motor drive : 3 KW

2) Reducer is passive : WPS70

3) Guide rail, slider : Brh-35

6. Auto roll welding machine (AC):

Model : FN-63KVA

7. Hydraulic cutting:

1) Shearing method : oil pressure with scrap flanged

2) Material of forming and shearing mould : Cr12M0V

3) Heat treatment method of shear blade : quenching treatment (HRC60-62)

4) Hydraulic system power : 30 T

4) Hydraulic motor : 5.5 KW

8. Electric control:

1) Electric box for PLC artificial intelligent control electric box

2) Electric box : MSGC dynamic 7 inch color touch screen

3) PLC control the whole line operation

4) Total machine weight : 6.5 T (approx.)

5) Total power : 15 KW

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.3-0.8mm | |

| Performance | Speed | Max. 30m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5T | |

| Main Machine | Main Roller Station | 11 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |