I. Profile: (according to confirmation by both parties)

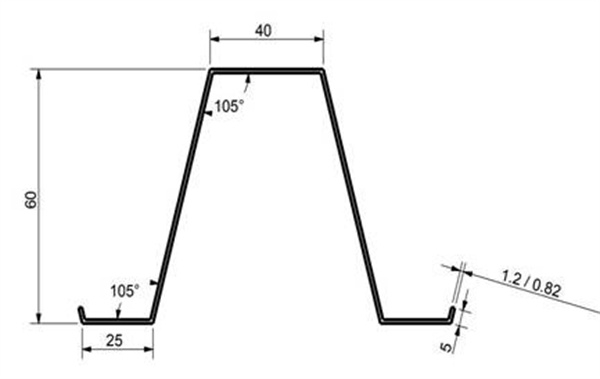

Profile – 1:

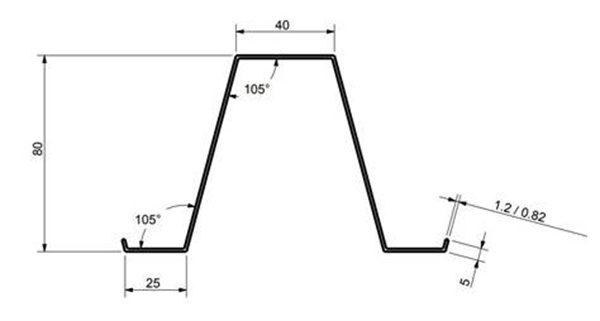

Profile – 2:

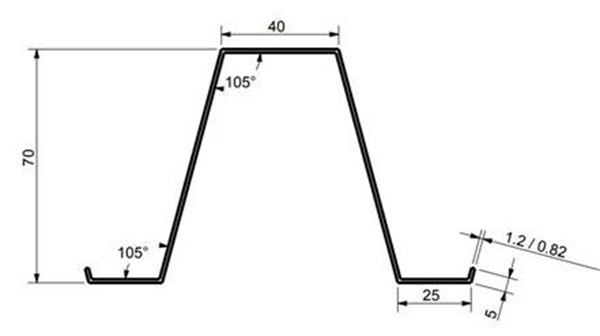

Profile – 3:

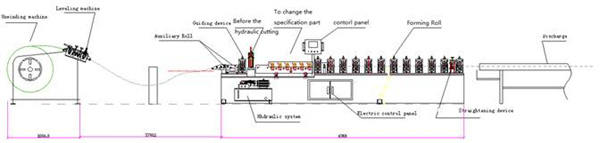

II. Process flow:

Uncoiling ------> Levelling -----> Guide Feeding -----> Hydraulic cutting (Pre-cutting) -----> Roll Forming -----> Auto unloading (Discharge table).

III. Main Component Data:

1. Suitable materials : Galvanized steel

2. Material thickness : 0.8-1.2mm.

3. Material width : 300mm.

4. Coil ID : 500mm

5. Coil OD : 900mm

6. Loading weight : 3000KG

7. Forming speed : 0-15 m / min

8. Feeding accuracy : L≤3000mm ± 1.0 (related to material quality)

9. Straightness accuracy : L≤1000mm ± 2.0 (related to material quality)

10. Power supply voltage : 415 V, 50Hz, 3Ph ,Drive motor 4KW+7.5

11. Feeding direction : feeding direction: form left to right (face to control panel),As per user

12. Transmission : cycloidal pin and chain transmission

13. Machine color : blue and orange red or as per buyer

IV. Main components of the Machine:

| Name | Model / Name | Quantity | Instructions |

| 1. Single head material rack | ML-400 | 1 set | Passive Uncoiling, Hydraulic expansion |

| 1. Main engine forming system | Feeding guide device | 1 set | horizontal direction |

| Horizontal rack | 18 nos | Lower shaft active move while upper shaft passive move, roll forming between 2 side plates | |

| Cut-off system | 1 set | Auto cut to length, hydraulic shearing | |

| 2. Unloading table | 1 set | Equip simple products blanking frame | |

| 3. Electric control system | 1 set | PLC Control system |

VI. Parameters of each component:

1. Uncoiling / leveling machine:

(1) Function : single head, hydraulic expansion

(2) Roll support : cantilever

(3) Unwinding method : Passive

(4) Tightening method : mechanical linkage

(5) Loading Capacity : 1000KG

(6) Coil I.D : 500MM

(7) Coil O.D : 700MM

(8) Uncoiler power : 3 KW

2. Hydraulic Cutting system (Pre Cutting):

(1) With hydraulic as shearing power, hydraulic components from joint venture brand.

(2) Shearing method: 3 specifications and 3 cutters mould. The work piece is auto cut off according to the parameters set by the touch screen, blade material Cr12mov, quenched, HRC60℃.

(3) Machine transmission parts use Taiwan TBI precision linear guide way.

(4) Hydraulic motor: 5.5kw

3. Roll Former:

1) Frame: Welding the overall structure from profiled steel,The plane of the frame is precisely processed by a gantry milling machine, Thickness 40mm,

2) Standing house side panel:individual standing house,After finishing the surface is blackened; horizontal axis diameter φ58, key 16mm.

3) Roll material: Cr15 mould steel, heat treatment: HRC58℃ after precision CNC processing. Hard chrome plated surface

4) Straightness: Single wheel structure, both up & down, left & right can be adjusted to guarantee products straightness.

5) Roller way qty. : 18 nos.

6) Forming speed : 0-15m/min

4. Unloading table:

(1) Material receiving roller size : 3000mm

(2) Structure : Independent agency

5. Electric control system:

(1) Frequency control of motor speed control of main drive motor, Equipped with PLC programmable controller, Rotary encoder controls length.

(2) With 7 inch color touch screen, control mode: touch screen and button control.

(3) With a handheld controller.

V. Working environment:

1. Environment temperature: -10℃~+40℃.

2. Relative air humidity: no more than 60% when +40℃, and no more than 95% when +25℃.

3. There is no material may cause explosion, nor gas that may corrode metal or damage insulating layer, and no conductive dust.

4. No rains or snows.

5. Power supply: voltage 380V±10%, 3-phase, frequency between 49.5-50.5 HZ

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.8-1.2mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 18 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |