I. Profile: (according to confirmation by both parties)

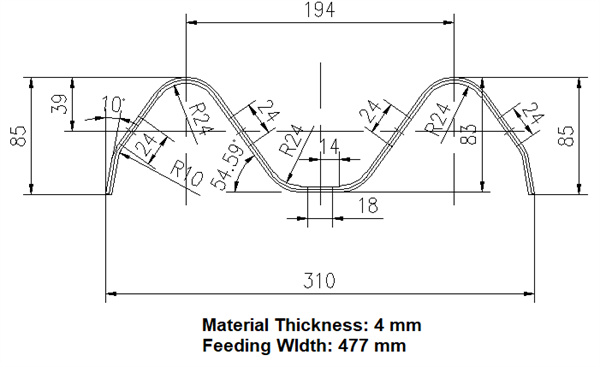

Guard Rail 2 Wave Profile:

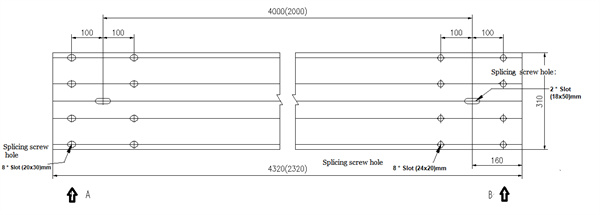

Punching Details:

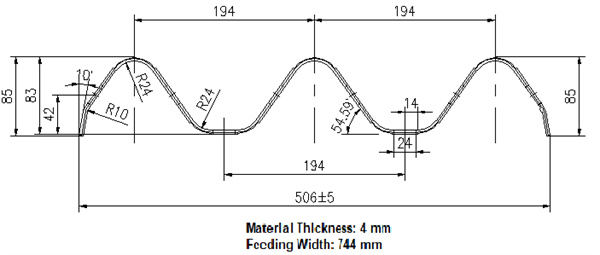

Guard Rail 3 Wave Profile:

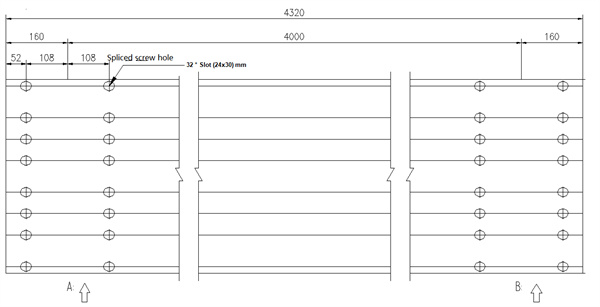

Punching Details:

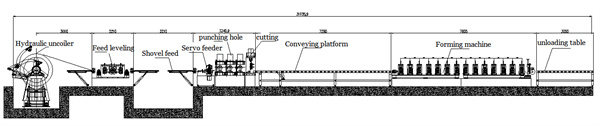

II. Process flow:

Auto Uncoiling -----> Level feeding -----> Servo feeding ------> Hydraulic punching & Cutting -----> Feeding table -----> Forming machine -----> Stacking

III. Main Component data:

1) Material : Q235

2) Thickness : 2.5- 4.0 mm

3) Width : 480mm-740mm

4) Coil I.D : 508 -600mm

5) Coil OD : ≤ 1900mm

6) Coil weight : ≤10T

7) Product width : 310mm-506mm

8) Product height : 85mm

9) Product length : 4320mm

10) Length tolerance : 4320mm±2mm

11) Forming method : roll cold bending forming

12) Production speed : ≤15m/min (4320mm length: 2-3pcs/Min)

13) Feeding direction : Feeding direction: form left to right (face

to control panel) ----- (as the user).

14) Main voltage : 415V, 50Hz, 3-Phase.

15) Total power of unit : about 70KW

IV. Machine Component details:

1. Hydraulic Uncoiler

(1) Uncoiler : Electric feeding, hydraulic expansion

(2) Loading Weight : 5T

(3) Uncoiler Coil I. D : φ508-610mm

(4) Uncoiler range : φ450-φ530mm-φ630mm

(5) Uncoiler feed width : ≤1200mm

(6) Uncoiler power : 5.5kw

(7) Uncoiler hydraulic system power : 3KW

(8) Uncoiler hydraulic system oil pump : vane pump

( 9) Uncoiler spindle diameter : φ190mm

(10) Unrolling tension cylinder diameter : φ200mm

2. Leveler:

(1) Wall plate type 9 roll leveler, 2 roll pinch, 7 roll leveler.

(2) Leveling roller diameter : 120mm.

(3) Leveling roller material : 40Cr, heat treated HRC48~52.

(4) Leveler motor power : 11KW, Variable frequency speed regulation,

ZQ350 reducer, speed ratio (i = 20.49)

(5) Leveling speed : 10-25 m/min

(6) Leveling feed width range : 300-800mm.

3. Servo feeder:

(1) Motor power : 4KW+ planetary reducer

(2) Ratio : 1:10

(3) Feeding roller diameter : φ120mm

(4) Material is 40Cr, heat treatment HRC48 ~ 52.

4. Hydraulic punching and cutting:

(1) Oil cylinder diameter: ¢ 250mm, ¢ 120mm stroke: 30mm, four-column structure, base adopts steel plate aging treatment.

(2) Roll forming mould : 3sets. Material GCr15

(3) Blade material : Cr12M0V quenching treatment (HRC58-62)

(4) Hydraulic pump : YBI-10,

(5) Hydraulic power : 30KW

5. Quick feed platform:

Speed ratio : 31.5;

Feeding roller diameter : φ120mm,

Material : 40Cr, heat treatment: HRC48~52.

6. Roll Former:

(1) Forming machine : 17 sets

(2) Independent open-standing house structure

(3) Guide vertical rollers : 5 nos

(4) Roller diameter : φ110mm, material 40Cr, tempering treatment.

(5) Single out shaft drive : GY230; Gearbox : 18pcs

(6) Forming machine motor power : 2 * 22KW

7. Stacking:

(1) Weld the square pipe ,with slide roller

(2) Lifting and stacking : 4 meters

(3) Lifting motor : 3KW

(4) Transverse motor : 1.5kw

(5) Cylinder swing unloading

| Raw Material | Type | Galvanized Sheet |

| Thickness | 2.5-4mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 10 T | |

| Main Machine | Main Roller Station | 16 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Gear Box | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |