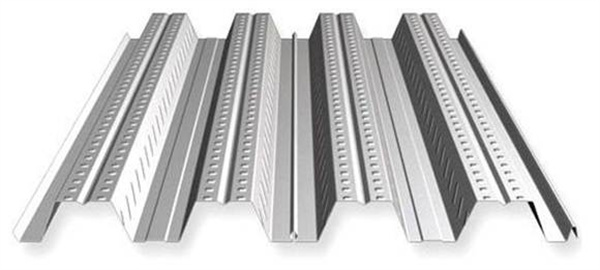

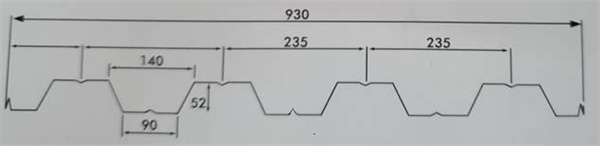

I. Profile drawing: (according to confirmation by both parties)

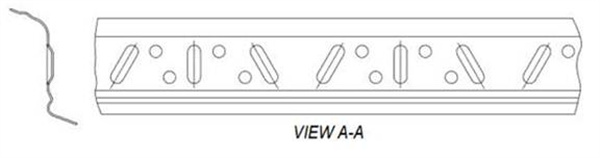

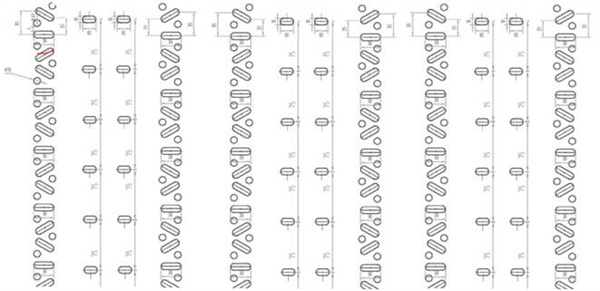

Embossing Details:

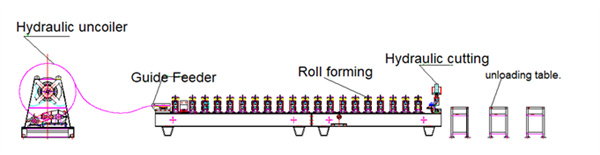

II. Process flow:

Active uncoiling ----> Guide Feeder ----> Roll forming ----> Length cutting ----> unloading table.

III. Main Components of the Machine Line:

1. Hydraulic Uncoiler:

(1) Uncoiler : Active feeding, Hydraulic expansion

(2) Loading Weight : ≤ 5 T

(3) Uncoiler Coil I. D : 508 mm

(4) Inner diameter of coil : (Φ470 - Φ560) mm

(5) Coil diameter : Φ 1500 mm

(6) Feeding width : ≤1250mm

(7) Uncoiler material : 40 Cr

(8) Motor Power : 5.5 KW

(9) Hydraulic motor power : 3 KW

(10) Hydraulic damping compression arm

2. Roll Former:

(1) Main frame: Steel Welding.

(2) Forming machine type : wall plate chain drive

(3) Shaft material : 40Cr quenching and tempering treatment (HB220-260)

(4) Shaft diameter : Φ95 (HRB Bearing)

(6) Forming machine motor power : 30 KW (15KW×2)

(7) Forming machine line speed : 0-18 m\min

(8) Roller stations : 33 Nos (with embossing)

(9) Thickness : (0.8-1.5) mm (Galvanized sheet, cold rolled sheet)

(10) Rolled material Yield strength : 350 MPa

(11) Unfold size : 1250 mm

(12) Length limit : ±1.5 mm

(13) Roll forming die : 1 set

(14) Roll material : 40 Cr quenching & tempering (HB220-260)

(15) Roller surface treatment : Hard chromium plating

2. Hydraulic cutting (Guide column type):

(1) Cutting type : after molding stop hydraulic cut off

(2) Forming cutting mold material : Cr12M0V

(3) Heat treatment of cutting blade : quenching treatment (HRC58-62)

(4) Motor power of hydraulic station : 5.5 KW

(5) Hydraulic station oil pump : vane pump or plunger pump

3. Unloading Table:

(1) Structure of unloading roller : Angle welding, drum type (no power)

(2) Material unloading roller size : 2200mm x 2pcs

IV. Equipment structure:

The main machine is composed of active uncoiler, Roll forming (including feeding, hydraulic cutting and unloading table), hydraulic system, electric control system, etc.

Machine picture: (only for your reference)

| Raw Material | Type | Galvanized Sheet, Cold Rolled Sheet |

| Thickness | 0.8-1.5mm | |

| Performance | Speed | Max. 18 m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5 T | |

| Main Machine | Main Roller Station | 33 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |