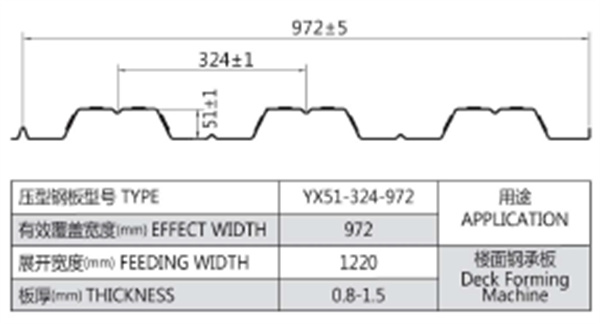

I. Profile drawing: (according to confirmation by both parties)

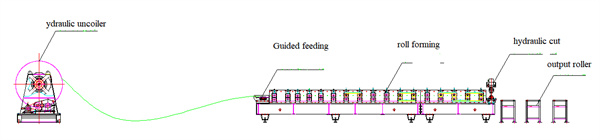

II. Process flow:

Automatic uncoiling → Guide Feeding → Roll forming → Hydraulic Shear → discharge table.

III. Components of the machine line:

1. Uncoiler:

1. Uncoiler type : Automatic uncoiler, Hydraulic expanding,

2. Uncoiler Capacity : 5 T

3. Motor power : 5.5 KW.

4. Feeding Width : 1220 mm

5. Hydraulic power : 3 KW

6. Uncoiler coil ID : 508 mm

2. Roll Former:

1) Main frame: High quality steel after welding and tempering

2) Feeding guide type : side roller

3) Forming machine type : wallboard chain transmission

4) Guiding Feeding frame : Side hand wheel type

5) Wall type with chain to drive

6) Quenching and tempering treatment (HB220 – 260)

7) Φ95 quenching and tempering treatment (Harbin Bearing)

8) Forming machine motor power : 2 * 18.5 KW

9) Forming machine speed : 0-15 m/min

10) Roll forming stations : 28 Stations

11)Thickness : (0.8 - 1.5) mm

12) Cut length : ±1.5 mm

13) Roller material : 45# steel

14) Roller hard chromium : ≥ 0.05 mm

3. Hydraulic Cutting:

1) Shearing way : Hydraulic shearing

2) Shearing blade material : Cr12M0V

3) Heat treatment method of shear blade : Quenching treatment (HRC58-62)

4) Hydraulic unit motor : 7.5 KW

5) Hydraulic oil pump : gear pump

4. Unloading Table:

(1) Unloading table size : 2000mm x 2 pcs

(2) Table structure : Roller structure, angle steel welding, no power.

Machine picture: (only for your reference)

IV Equipment structure:

The main machine is composed of automatic uncoiler, roller forming (Including guide feed, Hydraulic cutting, and unloading table), hydraulic system, electronic control system, etc.

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.8-1.5 mm | |

| Performance | Speed | Max.15 m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5 T | |

| Main Machine | Main Roller Station | 28 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |