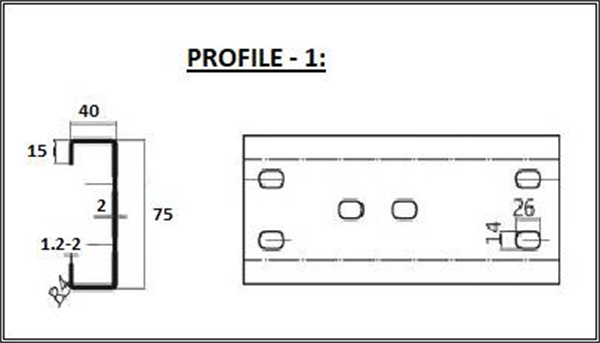

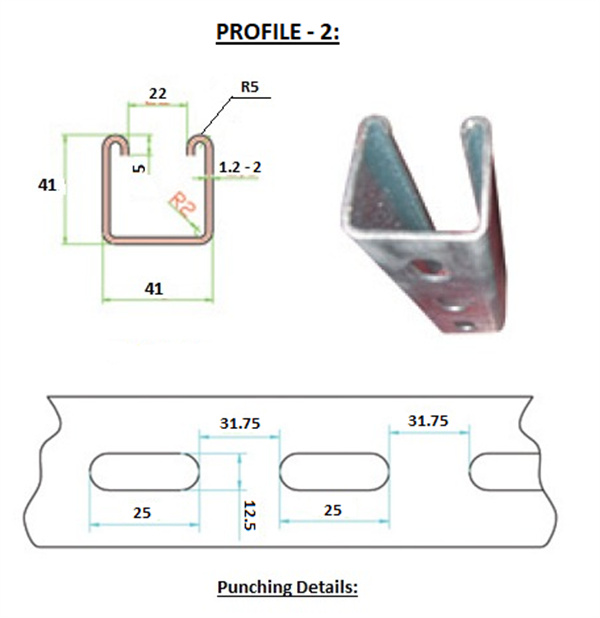

I. Profile drawing: (according to confirmation by both parties)

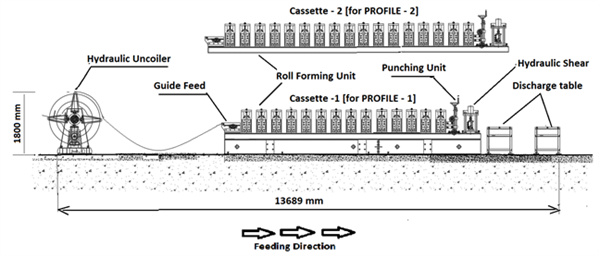

II. Process flow:

Passive Uncoiling -----> Guide Feeding -----> Roll forming -----> Punching -----> Hydraulic Shear -----> Discharge table.

III. Components of the Machine line:

1. Hydraulic Uncoiler:

1) Uncoiler type : Passive unwinding, Manual expanding.

2) Uncoiler Capacity : 3 MT

3) Feeding Width : ≤ 300 mm

4) Uncoiler Coil ID : Φ 508 mm

2. Roll Former:

1) Forming machine guide feeding rack form : lateral hand wheel type

2) Forming machine form : wall plate chain drive

[Different specifications only need to replace the (Cassette) forming frame]

3) Roll Stations: ‘C’ Section [Profile – 1] Cassette-1 : 14 Nos

Strut Channel [Profile – 2] Cassette – 2 : 17 Nos

4) Shaft diameter : Φ 70mm

5) Motor power of forming machine : 11 KW (share)

6) Linear speed of molding machine : 0-15 m\min

(Does not include punching and cutting time)

7) Frame adopts : I-beam welding

8) Rolling thickness : (1.5 - 2.0) mm

9) Length Accuracy : 10m ± 1.5mm

10) Roll material: single-piece forged bearing steel GCr15, quenched twice by fine turning, quenching hardness : HRC58-62°, hard chrome plating.

11) Blade material : Gcr12mov (2 pairs)

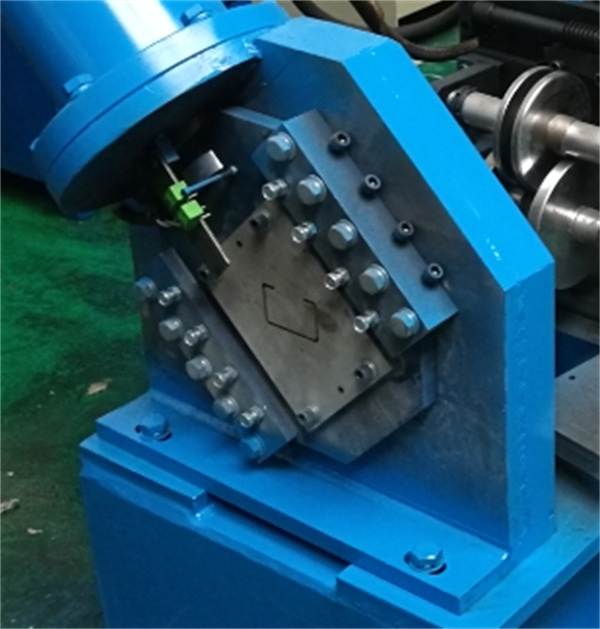

12) Punching mold: 2 sets of core-pulling molds (four guide pillars, ball and guide pillars are precisely guided, the upper and lower mold bases are high-quality 45#, all stripper plates, lower templates, and punch inserts are imported SKD11, and other templates are Cr12MoV ,)

3. Hydraulic station:

1) Hydraulic motor : 5.5 KW

4. Unloading table:

(1) Unloading table size : 1500mm x 2 pcs

(2) Unloading table structure : Roller structure, angle steel welding, no power.

Machine picture: (only for your reference)

V. Equipment structure:

The main machine is composed of uncoiler, 2 Nos of Roll forming Cassettes (Including Guide feed, Punching, Hydraulic cutting) Un-loading table), Hydraulic system, Electronic control system, etc.

| Raw Material | Type | Galvanized Sheet |

| Thickness | 1.5-1. 2mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Manual |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 14 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |