Parameter

| Sn | Name | Value | Unit | Remarks | |

|---|---|---|---|---|---|

| 1 | Spraying length | 13 | M | ||

| 2 | Max spraying steel tube diameter | Φ600 | Mm | ||

| 3 | Max spraying steel tube weight | 500 | Kg | ||

| 4 | Power | Electric heating | 180 | Kw/h | |

| Fuel | 22 | Kw/h | |||

| Coal | 20 | Kw/h | |||

| Gas type | 20 | Kw/h | |||

| 5 | Pweder oven size | L | 14000 | Mm | |

| W | 2100 | Mm | |||

| H | 3200 | Mm | Highest | ||

| 6 | Moveable spraying room size | L | 4800 | Mm | |

| W | 1300 | Mm | |||

| H | 2400 | Mm | |||

| 7 | Size | 20500 | Kg | ||

Figure

Characteristic

The room was combined by cold steel rolling plate, the structure was easy, and also easy for cleaning.color side was install the convulsions sets.at the same time we install the dust-proof floodlight.It was very easy to operate spraying.

It adopt spelling installing.there is ripple plate outside.the surface of the oven was rigour, firm,nice,with good heat insulation.the temperature adopt general electrical machine to control,work in heat wind circulate.to keep the temperature in the furnace equality.and fully satisfy powder with 180℃±5℃ require of solidifying.

Major dispositions

(1)powder room

(2)high-voltage electrostatic generator

(3)spray system(4 sets)

(4)powder pump recovery system

(5)0.5t hanging conveyor system(1 set)

(6)traversing car

(7)bake oven curing system(electric heating,fuel type,coal type,gas type)

(8)electrical control system(1set)

Parameters

| No. | Model | Value | Unit | |

|---|---|---|---|---|

| 1 | Diameter of grinding steel tube | Ø350 | Mm | |

| 2 | Length of grinding steel tube | 13000 | Mm | |

| 3 | Steel tube run around speed | 44326 | Turn/m | |

| 4 | Grinding steel tube run speed | 1100 | Mm/m | |

| 5 | Measure | L | 17000 | Mm |

| W | 2000 | Mm | ||

| H | 800 | Mm | ||

| 6 | Weight | 1500 | Kg | |

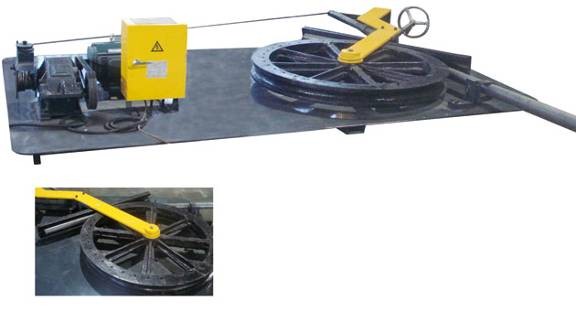

Figure

Description of machine

This machine steel tube adopt self-run and the movement of the machine in order to move the steel tube. The machine is fitted with grinding polishing bar, these grinding polishing bars will grind and polish the surface of steel tube quickly. It is speedy, efficient, saving workers and energy.it was the first choice for grinding and polishing every poles.

Two belts polishing at the same time, can install two different degree of belts, one-time polished finish.dust recycling automatically, to ensure that the operating environment of health, the light pole polishing after galvanized zinc dust can be effective recovery and sale, guarantee the health of workers, also can create value.

Spare parts supplier

| Sn | Name | Spec. | Qty | Supplier |

|---|---|---|---|---|

| 1 | Sand belt motor | 3kw | 1set | South anhui or siemens beide |

| 2 | Walking adjustable motor | 0.75kw | 1set | South anhui or siemens beide |

| 3 | Rotating motor | 0.55 kw | 1set | South anhui or siemens beide |

| 4 | Dustless motor | 3 kw | 1set | Shanghai |

| 5 | Electric components | 1set | Delixi,chint,schneider,siemens | |

| 6 | Reducer | Bwd150 | 1set | Dajiang |

| 7 | Rotating reducer | Bwd150 | 1set | Dajiang |

2. Equipment description:

1.1 mainly used for variety of lamps, piping system intersecting line plasma cutting.

1.2 applicable workpiece material:mild steel (copper nickel tube, stainless steel pipe required plasma cutting).

3. Parameters

| Sn | Name | Unit | Remark |

|---|---|---|---|

| 1 | Cutting diameter | Φ60-350 | Mm |

| 2 | Cutting tube wall thickness | 1~10 | Mm |

| 3 | Limited cutting workpiece length | 1000 | Mm |

| 4 | Require workpiece ovality | ≤1% | |

| 5 | Effective cutting length | 0-10 | M |

| 6 | Cutting speed | V≤3000(plasma) | Mm/min |

| 7 | Movement speed | V0=10~5000 | Mm/min |

| 8 | To be cut pipe maximum weight | 1500 | Kg |

Note:can be made according to your specific request

4. Motion axes:

| Axis of motion | Cutting machine axis number selection | 2 axis |

|---|---|---|

| X-axis: | The rotation axis of the pipe fittings | ★ |

| Y-axis: | Torch along the axial horizontal movement to the tube axis | ★ |

5. Cutting machine steel transmission forming and cutting types:

4.1 cutting machine steel transmission forming:chuck structure

4.2 cutting mode:plasma cutting

6. Machine configuration :

| Main components | Brand |

|---|---|

| Cnc system | Shanghai universal system |

| Drive system: | Servo motor and drive |

| Cutting system | Usa hypertherm system |

| Gearbox | Chinese brand |

| Line guide | Imported |

| Relay | Schneider |

| Switch | Domestic |

7. Models introduction:

Dmqg-500*10 lamp door cnc plasma cutting machine is the special machine from jiangsu tewei machine tool manufacturing co.,ltd, the machine has beautiful structure,low centre of gravity. Running steady.

Horizontal-end beam

Horizontal beam adopt gantry welding structure, with good overall rigidity and high strength. Each leading surface had been machining by precision machinery to ensure the correct position of movement. End beam drive adopt four rollers position. The verter of gravity is stead and ensure the good dynamic balancing. All the welding parts adopt entire anneal to release the stress and prevent the deformation of structure.

Guide rail

The vertical rail adopt high-strength rail, the top surface and sides are made by precision machining of special grainder.

Transmission

Vertical and horizontal transmission adopt high precision gear rack joogle. Together with accurate epicyclic gearbox to reduce speed. With high output torquemoment. Lower noise, long life smooth and so on features. It achieve high precision position and transmission. Accuracy level grinding teeth,hardened(carburized quenching)shaft gear. The transmission mechanism is life institution.

Drive system

Adopt japan yaskawa imported servo drive system. Sooth and reliable operation. High control accuracy.

8. CNC system:

Performance indicators:

System performance:

1.Temperature environment of the system working:-20℃ to +70℃

2. Fluctuation range of the grid voltage system can be able to withstand:ac 220v

3. Control accuracy:±0.01 mm

System features:

9. Main configuration:

| Major equipment components name | Specifications or model | Unit | Qty |

|---|---|---|---|

| Cnc cutting machine host | Dmqg-500*10 | Set | 1 |

| Longitudinal rails | Tewei | Pieces | 2 |

| Longitudinal 7 gradeprecision rack | Tewei | Pieces | 3 |

| Cnc system | Shanghai | Set | 1 |

| Reducer | Boneng drive | Set | 1 |

| Digital servo and drive motor | Japan | Sets | 2 |

| Plasma system | Hypertherm | Set | 1 |

| Lifting device | Tewei | Set | 1 |

| Arc adjusting device | Tewei | Set | 1 |

| Electrical control cabinet | Tewei | Set | 1 |

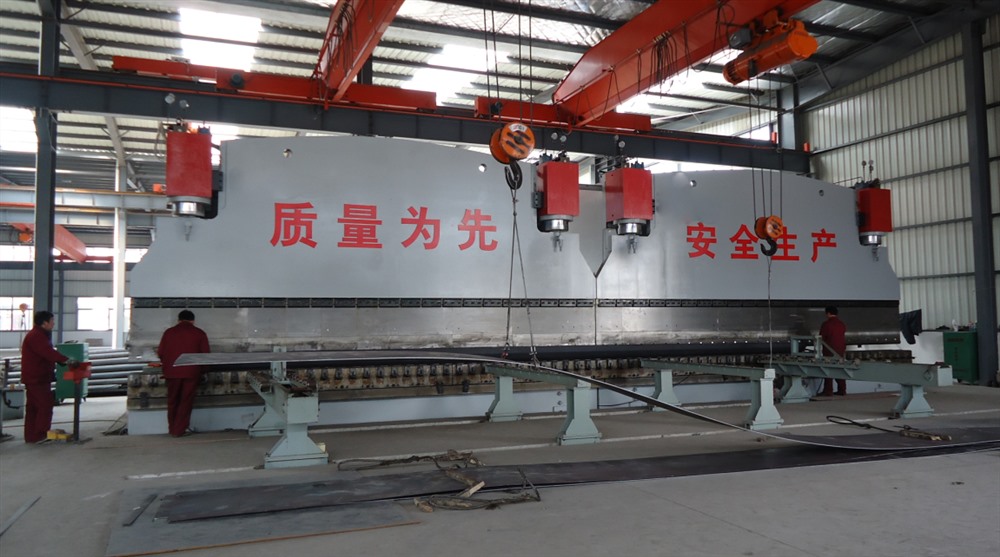

Photo

Parameters

| No. | Model | Value | Unit | Note | |

|---|---|---|---|---|---|

| 1 | Bending diameter | Φ90 | Mm | ||

| 2 | Bending radius | R500,r700 | Mm | 2 sets of round mould | |

| 3 | Bending tube thickness | 4 | Mm | ||

| 4 | Motor power | Model | Y132s-6 | Mm | |

| Power | 3 | Kw | |||

| Rotate speed | 960 | Rpm | |||

| 5 | Size | L | 3000 | Mm | |

| W | 2300 | Mm | |||

| H | 620 | Mm | |||

| 6 | Weight | 2300 | Kg | ||

| 9 | Submerged arc welding machine | 630a | 1set | Shanghai | |

| 10 | Wire feeding | 1set | Shanghai | ||

| 11 | Recycling machine | 1set | Wuxi | ||

| 12 | Line panel | 1pcs | Home made | ||

Description:

This equipment composed by the board and bending mode, with two sets of molds. Direct mode traction motor reducer, will die on the pressure in the round steel bar along the curved arc surface, simple operation, without heating and filler, economic benefits, compared with the industry's large-scale bending machine is similar effect, is steel manufacturer of equipment necessary.

Spare parts suppliers

| Sn | Name | Spec. | Qty | Supplier |

|---|---|---|---|---|

| 1 | Motor | 3kw | 1set | South anhui or siemens motor |

| 2 | Reducer | Zq250 | 1set | Shanghai |

| 3 | Electric components | 1set | Delixi,chint,schneider,siemens | |

| 4 | Bending die | Radius 500mm | 1pcs | Home made |

| 5 | Bending die | Radius 700mm | 1pcs | Home made |

Parameter

| No. | Model | Value | Unit | |

|---|---|---|---|---|

| 1 | Straighten length | Unlimited | ||

| 2 | Maximal straighten diameter of tube | Φ600 | Mm | |

| 3 | Maximal thickness of steel tube | 10 | Mm | |

| 4 | Power of motor | Model | Y160m-6 | Mm |

| Power | 11 | Kw | ||

| Rotate speed | 960 | Rpm | ||

| 5 | Size | L | 4000 | Mm |

| W | 1280 | Mm | ||

| H | 2450 | Mm | ||

| 6 | Weight | 2700 | Kg |

Figure

This machine with easy and compact structure, convenient and reliable.the time of putting steel pole to penetrator can be fit by workers.the workers hold the press-button press molding, the linearity was fit by eyes of the workers, it is with high efficiency.

Spare parts supplier

| Sn | Name | Spec. | Qty | Supplier |

|---|---|---|---|---|

| 1 | Oil pump | 25 above dispalcement | 1set | Shanghai |

| 2 | Motor | 11kw | 1set | South anhui or siemens motor |

| 3 | Sealings | Full set | 1set | Japan |

| 5 | Hydraulic oil | 46# anti-wear hydraulic oil | 1barrel | Shanghai(charged by user) |

| 6 | Hydraulic valve stack | Dedicated system | 1set | Home made |

| 7 | Cylinder | Dedicated cylinder | 1set | Home made |

Main technology parameter

| No. | Model | Value | Unit | ||

|---|---|---|---|---|---|

| 1 | Seam length | ≤13000 | Mm | ||

| 2 | Max seam thickness | 8 | Mm | ||

| 3 | Host header size(l*w*h) | 1500*480*1645 | Mm | ||

| 4 | Worktable size(l*w*h) | 13500*400*480 | Mm | ||

| 5 | Max seam diameter | Φ400 | Mm | ||

| 6 | Min seam diameter | Φ60 | Mm | ||

| 7 | Welding current | 630 | A | ||

| 8 | Walking device motor | Model | Yct160-4b | 8 | |

| 9 | Oil pump motor | Model | Y2100l2-4 | 9 | |

| 10 | Recovery motor | Model | Y100l-2 | 3 kw | |

| 11 | Gear pump | Model | Cbn-e306 | 25ml/r | |

| 12 | Max pressure system | 10 | Mpa | ||

| 13 | System working pressure | ≤5 | Mpa | ||

| 14 | Machine size | r | 31000 | 14 | |

| W | 1600 | ||||

| H | 1650 | ||||

| 15 | 5800 | Kg | |||

Photo

This machine composed by main machine head, tractive body and feeding shelf. Tractive body was moved by collet in small vehicle nipping the steel pole’s collet. When the small vehicle moved, drives steel pole, from small collet to big collet, regularity moved. The big side of the steel pole was hold by feeding vehicle, force automatic sewing from head of machine to steerable wheel. At one time, the welding machine starts welding. This machine adopts multiple wire submerged arc welding, solder was reclaimed automatic. Welding line was symmetrical and slinky. It has strong filter, forming one time, And be with high welding efficiency. The speed of welding achieve 2 to 3 meters per minutes, is about 3 times of the gas welding. The cost of the welding is lower than gas weldong. It is with speedy welding, high efficiency, and lowest price in china light poles industry now.

Welding light pole, high light pole, power pole body

Main spare parts supplier

| Sn | Name | Spec. | Qty | Supplier |

|---|---|---|---|---|

| 1 | Gear pump | 25 above displacement | 1set | Huaiyin |

| 2 | Gear pump motor | 3kw | 1ste | South anhui or siemens motor |

| 3 | Bencher | 3kw | 1set | South anhui or siemens motor |

| 4 | Reducer | Bwd220 | 1set | Dajiang |

| 4 | Sealings | Full sets | 1set | Import from japan |

| 5 | Electric components | 1set | Delixi,chint,schneider,siemens | |

| 6 | Hydraulic oil | 46# anti-wear hydraulic oil | 1barrel | Shanghai(charged by user) |

| 7 | Bearings | 1set | Harbin | |

| 7 | Hydraulic valve stack | Dedicated system | 1set | Home made |

| 8 | Cylinder | Special cylinder | 1set | Home made |

| 9 | Submerged arc welding machine | 630a | 1set | Shanghai |

| 10 | Wire feeding | 1set | Shanghai | |

| 11 | Recycling machine | 1set | Wuxi | |

| 12 | Line panel | 1pcs | Home made |

1. Figure

2. Technique parameters of machine

| Sn | Name | Unit | Value | ||

|---|---|---|---|---|---|

| 1 | Nominal pressure | Kn | 2*4000 | ||

| 2 | Bending length | Mm | 2*65000 | ||

| 3 | Column gaps | Mm | 5600 | ||

| 4 | Slider stroke | Mm | 320 | ||

| 5 | Max opening height | Mm | 1050 | ||

| 6 | Throat depth | Mm | 1000 | ||

| 7 | Width of table | Mm | 450 | ||

| 8 | Slider velocity | Idle load | ≥90 | ||

| 9 | Working | 8 | |||

| 10 | Return | ≥70 | |||

| 11 | Main motor power | Kw | 2*30 | ||

| 12 | Size(l×w×h) | Mm | 2 x 6500x2900x5250 | ||

| 13 | Machine weight | Kg | 2*55000 | ||

| 15 | Machine accuracy | Slider repeatability | Mm | ≤0.02 | |

| 16 | Slider positioning accuracy | Mm | ≤0.02 | ||

| 17 | Workpiece straightness | Mm | 0.75/m | ||

| 18 | Bending angle error | ′ | <45/m | ||

| 19 | Grating resolution | Mm | 0.005 | ||

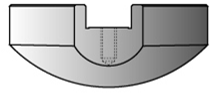

(2). Bottom dies: One set of combination die, v type bottom die open, length is 14000mm.

8. Press brake front and back feeding

(1). Front feeding

(2). Back feeding and side discharging

Technique parameters of the machine

| No. | Model | Value | Unit | |

|---|---|---|---|---|

| 1 | Diameter of grinding steel tube | Ø350 | Mm | |

| 2 | Length of grinding steel tube | 13000 | Mm | |

| 3 | Steel tube run around speed | 5-10 | Turn/m | |

| 4 | Grinding steel tube run speed | 1100 | Mm/m | |

| 5 |

Measure | L | 17000 | Mm |

| W | 2000 | Mm | ||

| H | 800 | Mm | ||

| 6 | Weight | 1500 | Kg | |

use

This machine is suitable for the plate cutting processing specially the long plate. Easy of operating and processing of optional length of the plate make the machine productive. Pressing the plate which needs to cut to walking-equipment through the hydraulic cylinder and shear it by revolving cutter accompanied the movement of the walking-equipment. It can also cuts taper plate according to the request inclination. Therefore, this machine is widely used in the processing of light pole, vessel, metal structure, ships, building, hardware and so on.

· machine overview

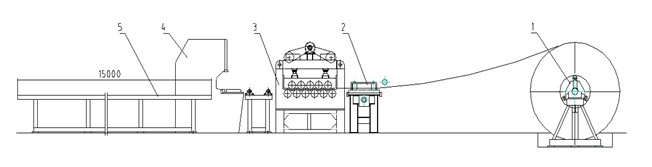

This machine used to spread the steel coil, leveling and cut to the request size.after manual feed into the leveling machine, as the cutting size, the unit will finish the leveling and cutting action.

· cut to length line working process:

1).decoiler

2.)side guiding unit

3).leveling machine

4).cutting machine

5).stack table

6).electric system

| No. | Model | Value | Unit | |

|---|---|---|---|---|

| 1 | Diameter of grinding steel tube | Ø350 | Mm | |

| 2 | Length of grinding steel tube | 13000 | Mm | |

| 3 | Steel tube run around speed | 5-10 | Turn/m | |

| 4 | Grinding steel tube run speed | 1100 | Mm/m | |

| 5 |

Measure | L | 17000 | Mm |

| W | 2000 | Mm | ||

| H | 800 | Mm | ||

| 6 | Weight | 1500 | Kg | |

| No. | Model | Value | Unit | |

|---|---|---|---|---|

| 1 | Diameter of grinding steel tube | Ø350 | Mm | |

| 2 | Length of grinding steel tube | 13000 | Mm | |

| 3 | Steel tube run around speed | 5-10 | Turn/m | |

| 4 | Grinding steel tube run speed | 1100 | Mm/m | |

| 5 |

Measure | L | 17000 | Mm |

| W | 2000 | Mm | ||

| H | 800 | Mm | ||

| 6 | Weight | 1500 | Kg | |