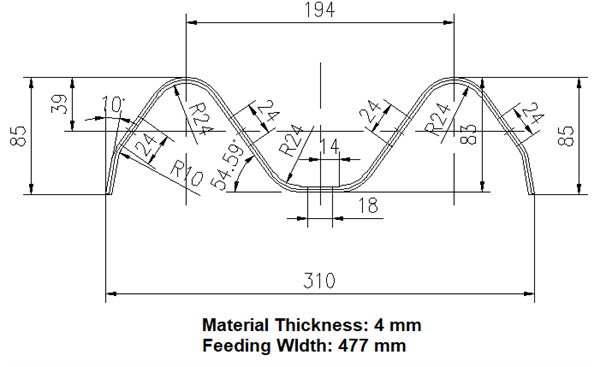

I. Profile: (according to confirmation by both parties)

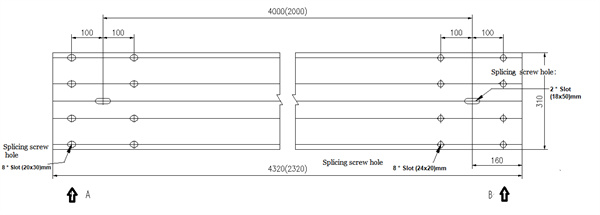

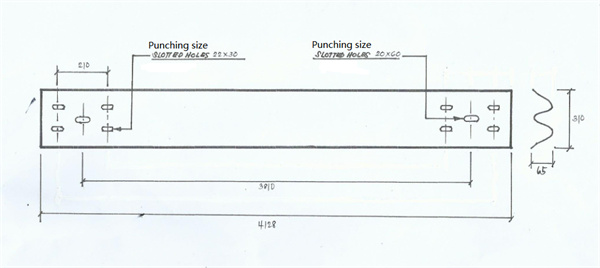

Punching Details:

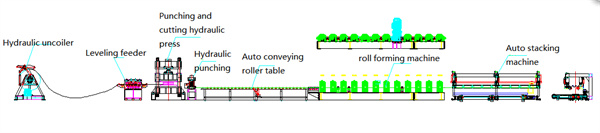

II. Process flow:

Auto uncoiling ------> 7 roller leveling ------> Servo feeding -------> Hydraulic punching and cutting -------> Conveying Roller table -------> Forming machine -------> Unloading.

III . Main Component Data:

1. Hydraulic Uncoiler:

(1) Uncoiler : Electric feeding, hydraulic expansion

(2) Loading Weight : ≤ 6T

(3) Uncoiler Coil I. D : φ508mm

(4) Uncoiler range : φ450-φ520mm

(5) Uncoiler feed width : ≤1200mm

(6) Uncoiler power : 5.5 kw

(7) Uncoiler hydraulic system power : 3kw

(8) Uncoiler hydraulic system oil pump : vane pump

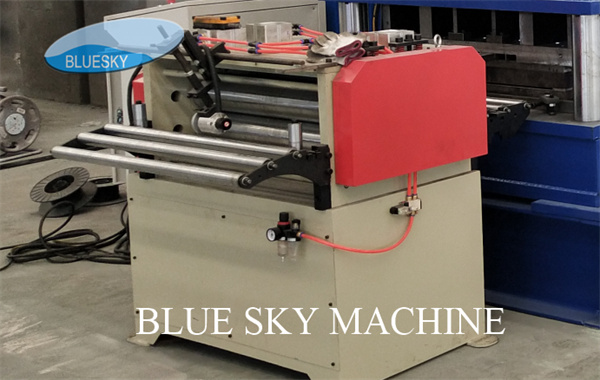

2. Leveler:

(1) Leveling machine structure : Wall type gear :(2 roll pinch, 7 roll leveler)

(2) Leveling roller diameter : 100mm.

(3) Leveling roller material : 40Cr, heat treated HRC (48~52).

(4) Leveler motor power : 5.5KW

(5) Leveling speed : 10-25M / min

(6) Suitable width : ≤500mm.

3. Servo feeder:

(1) Motor power : 2.9KW

(2) Feeding roller diameter : φ80mm

(3) Material is 40Cr; heat treatment HRC48 ~ 52.

(4) pinch roller pinch Power supply : Cylinder

4. Hydraulic punching and cutting:

(1) 4-column hydraulic press (two stations)

(2) Punching hole mould: 2 sets.

(3) Upper and lower mould material : Cr12Mov.

(4) Heat treatment of upper and lower mould: whole quenching, hardness HRC (58 ~ 62).

(5) Hydraulic system structure : two circuits

(6) Hydraulic station oil pump : plunger pump

(7) Hydraulic station motor : 22KW

(8) Hydraulic station cooling way : air cooling

5. Auto feed platform:

(1) Conveyor roller table size : 5000mm

(2) Conveying roller structure : square tube welding, drum conveying

(3) Conveying roller diameter : φ60mm

(4) Transmission mode : chain transmission

(5) Motor power: 1.5kw (adjustable-speed motor, adjustable feeding speed)

6. Roll Former:

(1) Frame: aging treatment of high quality section steel after welding

(2) Guide feed rack type : side roller type

(3) Guide roller material : Gcr15 quenching treatment (HRC58-62)

(4) Forming machine structure: cast-iron arch gearbox drive (universal joint)

(5) Shaft material : 40Cr tempering treatment (HB220-260)

(6) Shaft diameter : Φ80 (HRB bearing )

(7) Forming machine motor power : 22KW

(8) Forming machine line speed : 0-20m/min (not include punching and

cutting)

(9) Roller stations : 12 nos

(10) Rolling thickness : 3 mm

(11) Expand the width of the rolled material: Based on actual test machine plate width.

(12) Length accuracy : ±1.5mm

(13) Roll forming mould : 1 set

(14) Roll material : Gcr15 (forging)

(15) Roller heat treatment : quenching treatment (HRC58-62)

7. Auto stacking:

(1) Stacking size : 4000mm

(2) Weld the square pipe, with slide roller

(3) Motor down : 3KW

(4) Transverse motor : 1.5kw

(5) Cylinder swing unloading

| Raw Material | Type | Galvanized Sheet |

| Thickness | 3mm | |

| Performance | Speed | Max. 20m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 6 T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |