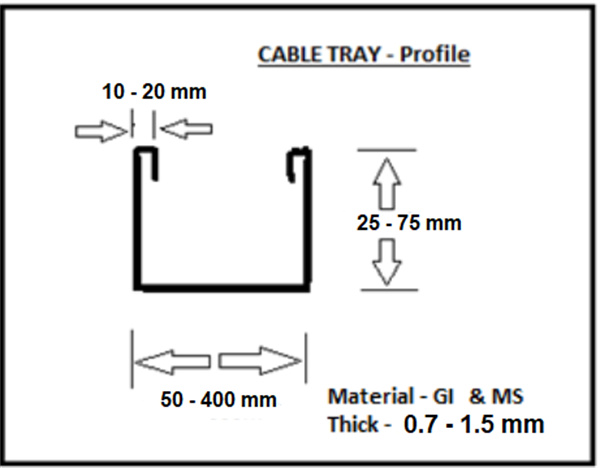

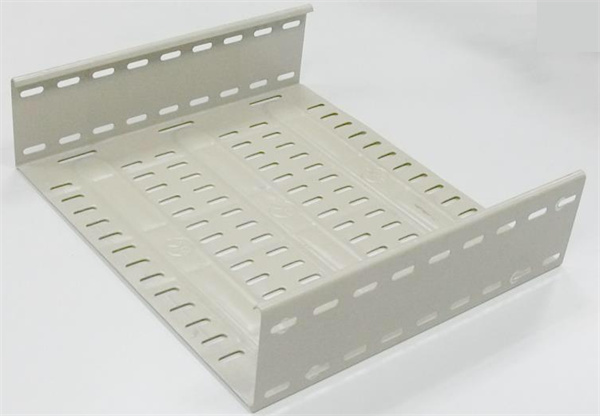

I. Profile drawings: (according to confirmation by both parties)

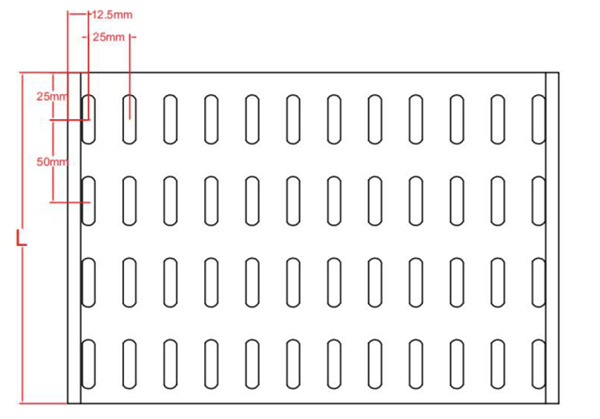

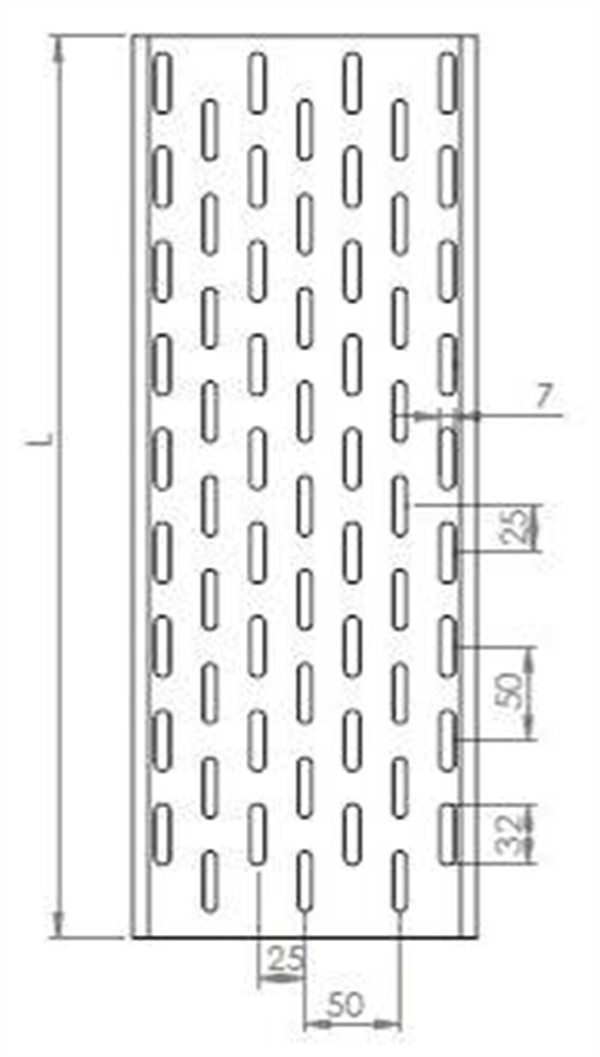

Punching Details will be as per below specifications:

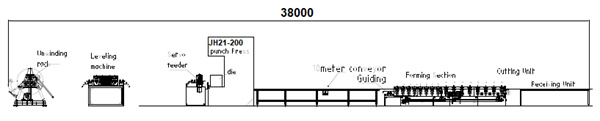

II. Process flow:

Automatic De-coiler ----> Levelling Machine ----> Servo Feeding Machine ----> Punching Press ----> Conveyor table -----> Roll forming ----> Hydraulic cutting (servo tracking) -----> (Collection) Discharge table.

III. Main Component Dates:

Machine Specifications:

1) Area of production line : 38m * 3.5m * 5m (L * W * H).

2) Feeding direction : from left side to right side

3) Power Supply : 380V, 50Hz, 3-phase

4) Pneumatic station : Pressure 0.7 MPa, 0.5M3/min.

5) Hydraulic oil : 46# Hydraulic oil

6) Gear oil : 18# gear oil

Finished Product Range:

1. Thickness of material sheet : 0.7 ~ 1.5 mm

2. Material : Cold steel coil, Hot steel coil

3. Coil Weight (max) : 3 T

4. Line speed with punching : 5 - 8 m/min

5. Length of finished product : 1000 - 6000 mm

6. Straightness tolerance of finished product : 1 - 1.5 mm / 1500 mm

7. Angle tolerance of finished product : ≤±1.5 / 1000 mm

8. Anti-hazard classification of motor : ExdIICT4

9. Grade of Protection of motor : IP55

10. Total power : about 80 KW

11. Cable tray, Maximum thickness : 0.7 ~1.5 mm

12. Width of product : 50 - 400 mm

13. Maximum height of product : 25 - 75 mm

IV. Components of the Machine Line:

1. Automatic De-coiler:

1) Width of material sheet : (200 - 800) mm,

2) Thickness of material sheet : (0.7 ~ 1.5) mm

3) Inner diameter : 508 mm

4) Range of expanding : ф480 - ф520 mm

5) Maximum outer diameter : φ1100 mm, Loading: ≤ 3 MT

6) Power of motor : 5.5 KW frequency controlled

7) Type of expand : Hydraulic expanding.

8) Type of press coiler : Air-powered press

9) Feeding speed : 0-10 m/min, adjustable.

BenQ Digital Camera

2. Leveling machine:

BenQ Digital Camera

1) Working roller : Nine rollers type leveling machine 3. NC1250 servo feeding machine:

BenQ Digital Camera

1) Function: material feeding

2) Feature: Uses the servo motor-driven .Multistage type feeding: May input 10 group of different feeding lengths, The liquid crystal touching screen demonstrated is advantageous for the change, establishes various technical parameters. The auto-induction start system and the punch press linkage (control punch press start).

4. Punching press:

(Only for reference….!)

1) Type of punching press : JF21-200

2) Punching press : Uses the steel plate welding fuselage, the rigidity is strong with good appearance .Uses the combined type air operated friction clutch.

5. Hydraulic cutting device:

BenQ Digital Camera

1) Type: hydraulic cutting

2) Punching mould is located end of hole punching section, it is separate operation device, the servo-feeder to position the length and cutting. The material of cutting blade is Cr12MoV, can the working piece without burr and also have the feature of easy change and long service life.

6. Convey guide station:

1) Type : Power roller wheeled (conveying the material)

2) Function and structure : Can feed the sheet to the forming machine smoothly, the guide device is composed by the air cylinder. The guide wheel may adjust conveniently, adapts the different width sheet.

3) Technical parameter : Material width (200 – 1000) mm

BenQ Digital Camera

7. Roll Former:

1) Forming station : 22 stations

2) Width of feeding : 200~800mm

3) Bearings diameter of forming mould : 65 mm

4) Distance of level rollers : about 350-550mm

5) Power of motor : 15 KW

6) Production speed : 5 - 8 m/min

8. Unloading table:

Structure: roller type with no power

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.7-1.5mm | |

| Performance | Speed | Max.10 m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 22 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |