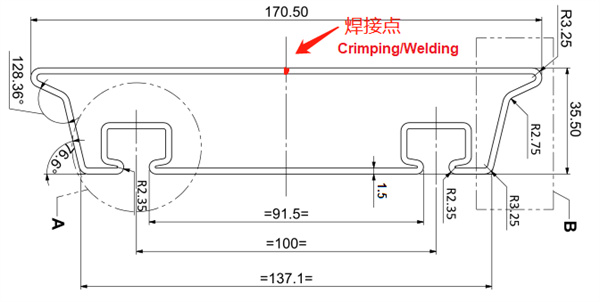

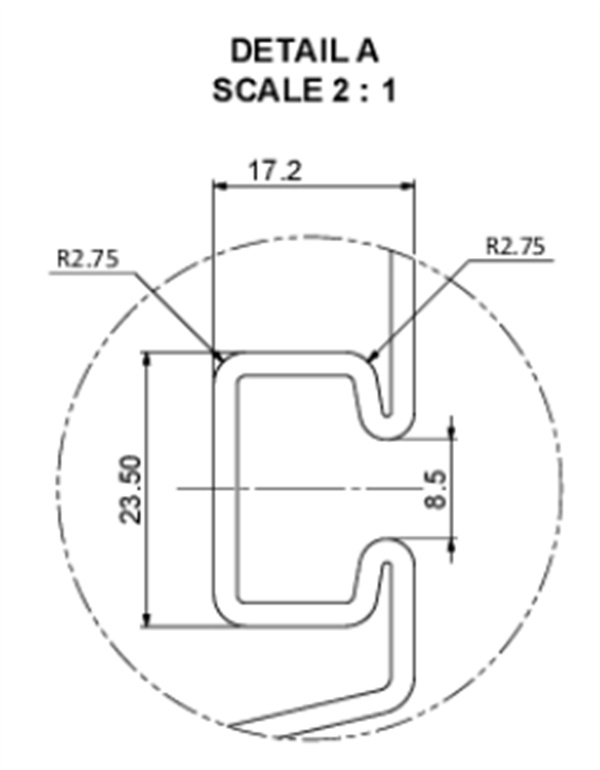

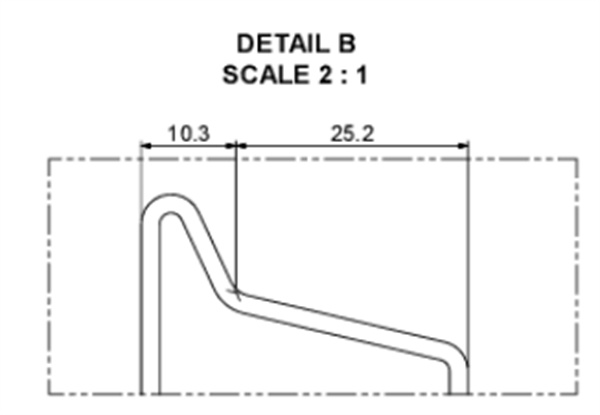

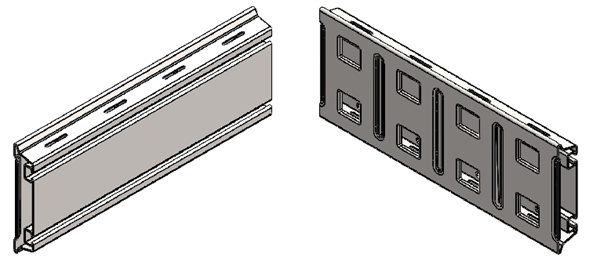

I. Profile drawing: (according to confirmation by both parties)

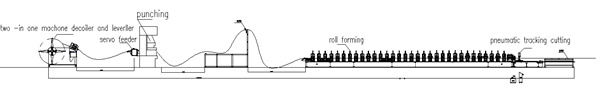

II. Process flow:

Feeding and leveling machine -----> Servo feed + (160T punch) ------> Guide feed ------> Roll forming -------> Hydraulic Shear (Servo tracking) -----> Discharge table.

III. Components of the Machine Line:

1. Unwinding and leveling machine:

1) Uncoiler : passive unwinding, hydraulic tensioning

2) Unwinding machine load : 5 MT

3) Inner diameter of unwinding machine support roll : φ508 mm

4) Range of support roll : φ450-530 mm

5) Power of hydraulic system of decoiler : 1.5 KW

6) Oil pump of uncoiler hydraulic system : gear pump or vane pump

7) Leveling mechanism structure : two-roller pinch feeding, seven-roller leveling

8) Diameter of leveling roller : about φ70mm

9) Leveling roller material : high quality 40Cr

10) Heat treatment method of leveling shaft: surface high frequency quenching treatment

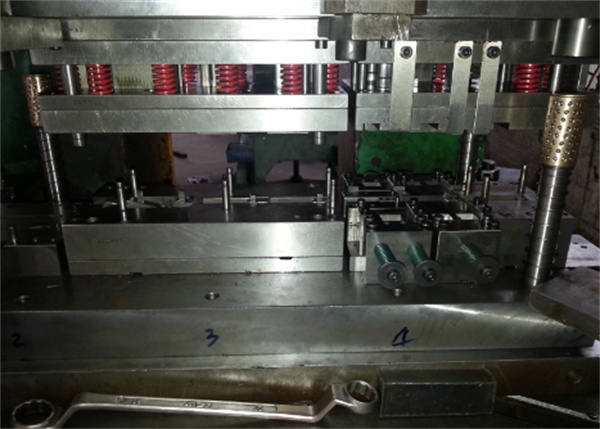

2. Servo feed punching mechanism:

1) Model of feeder : NC-500

2) Servo motor power : 3 KW + planetary reducer (1:7)

3) Punch : 160T

4) Punching die : 1 set (continuous die)

5) Material of upper and lower mold : SKD11

6) Heat treatment method of upper and lower molds: quenching treatment (HRC58-62).

7) Template material: No. 45 carbon steel quenched and tempered after grinding.

(This picture is only for reference)

(Mould picture for reference)

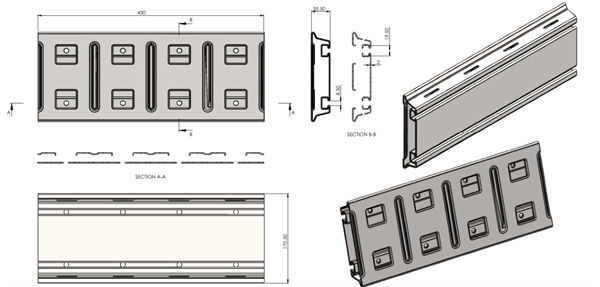

3. Roll Former:

1) Profile section : subject to confirmation by both parties

2) Applicable plate: Material : HR Steel (Coil) hot rolled coil

Material Grade : S550MC, HSFQ 550

YS Range (min & max) Yield strength: 350 – 650 Mpa

Thickness Range : (1.2 - 1.5) mm

Coil Width (max) : 600 mm

Coil Weight : 10 MT (max)

Length range : (250 – 3000) mm

3) Sheet width : subject to actual test machine

4) Frame: high-quality I-shaped steel after aging treatment (CNC gantry milling machine processing)

5) Forming machine form : Torii chain transmission

6) Linear speed of forming machine : 0-10 m\min

7) Number of molding channels : 36 channels

8) Main motor power : 22 KW

9) Reducer : Hardened gear reducer (K series)

10) Spindle material: high quality 40cr quenching and tempering treatment (HB220-260)

11) Shaft diameter : Φ70 (super precision grinding after CNC turning)

12) Roll mold : 1 set

13) Roll material: Gcr15 (CNC processing, hard chromium plating on the surface)

14) Roll heat treatment method : quenching treatment (HRC58-62)

4. High frequency argon arc welding:

Air compressor needs to be equipped separately. (Flow rate is 0.5m3/min; pressure is 0.6MPa.)

1. Welding method : tracking welding

2. Servo motor : 0.85 KW.

3. Multi MIG350 CO2/MAG welding power source;

4. MIG350 CO2/MAG welding power supply.

5. Hydraulic Shear (Servo tracking):

1. Cutting method : Pneumatic tracking flying saw cutting

2. Air source : Flow rate is 0.5m3/min; pressure is 0.7MPa.

3. Shear die base : High-quality carbon steel after welding and tempering

treatment

4. Motor power : 7.5 KW

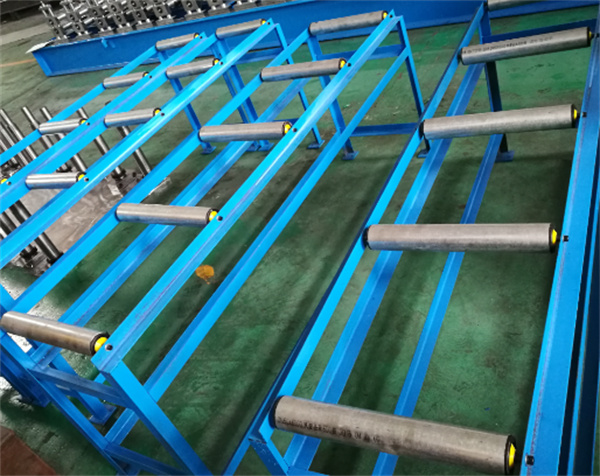

6. Unloading table:

1. Material receiving roller structure : no power roller type (angle steel welding)

2. Specification of receiving roller : 2000mm x 2 pieces

| Raw Material | Type | Galvanized Sheet |

| Thickness | 1.2-1.5mm | |

| Performance | Speed | Max. 10m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 10T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |