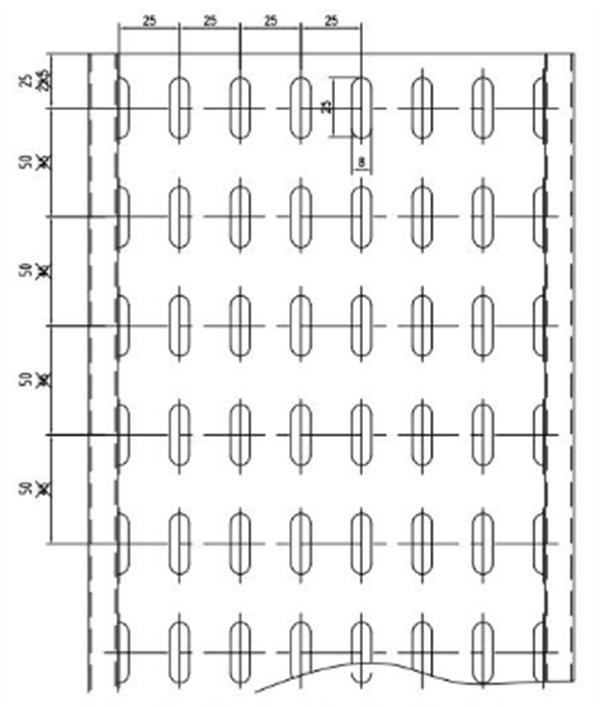

I. Profile drawing: (only for you reference)

Holes punching stations: (holes diameter will be confirmed by the customer)

1.1 Technical parameters of machine

1.1.1 Area of production line : length 38m x width 3.5m x height 5m

1.1.2 Feeding direction : from left side to right side

1.1.3 Power : 380V, 50Hz, 3 phase

1.1.4 Pneumatic station : pressure 0.-0.7MPa.,0.5M3/min.

1.1.5 Hydraulic oil : 46# Hydraulic oil

1.1.6 Gear oil : 18# gear oil

1.2 Main technical parameters

1.2.1 Width of material sheet : 200-950mm

1.2.2 Thickness of material sheet : 1.0~1.5mm

1.2.3 Material : cold steel coil / Hot steel coil

1.2.4 Line speed with punching : 2-5 M/min

1.2.5 Length of finished product : 2000-6000mm (2440/3000mm)

1.2.6 Straightness tolerance of finished product : 1—1.5 mm /1500 mm

1.2.7 Angle tolerance of finished product : ≤±1.5/1000mm

1.2.8 Anti-hazard classification of motor : ExdIICT4

1.2.9 Grade of Protection of motor : IP55

1.2.10 Total power : about 65KW

2.Forming product range:

2.1 Cable tray, Maximum thickness : 1.0~1.5mm

2.2 Width of product : 50-600mm

2.3 Maximum height of product : 150mm

3. General structure of equipment:

3.1 Manufacturing technique:

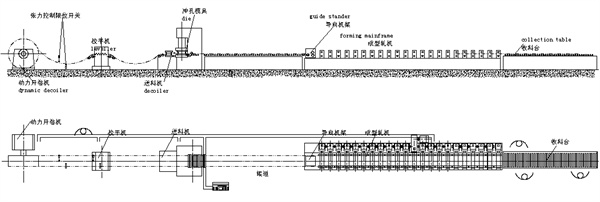

3.1.1 2 Scheme drawing of production line:

II. Equipment consists:

Auto-De-coiler --- leveling machine --- Servo feeding machine --- Punching press --- Hydraulic cutting --- Feeding frame --- Forming machine --- Collection table

4.2 General structure of equipment

4.2.1 Auto de-coiler BSD-1000

BenQ Digital Camera

4.2.2 Leveling machine BSL-1000

BenQ Digital Camera

4.2.3 BSNCF-1000 servo feeding machine

BenQ Digital Camera

4.2.4 Punching press

Only for reference!

4.2.5 Hydraulic cutting device

BenQ Digital Camera

The material of cutting blade is Cr12MoV, can the working piece without burr and also have the feature of easy change and long service life.

4.2.6 Convey guide station

BenQ Digital Camera

4.2.7 Main forming machine

| Raw Material | Type | Galvanized Sheet |

| Thickness | 1.0-1.5mm | |

| Performance | Speed | Max. 10m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5 T | |

| Main Machine | Main Roller Station | 22 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |