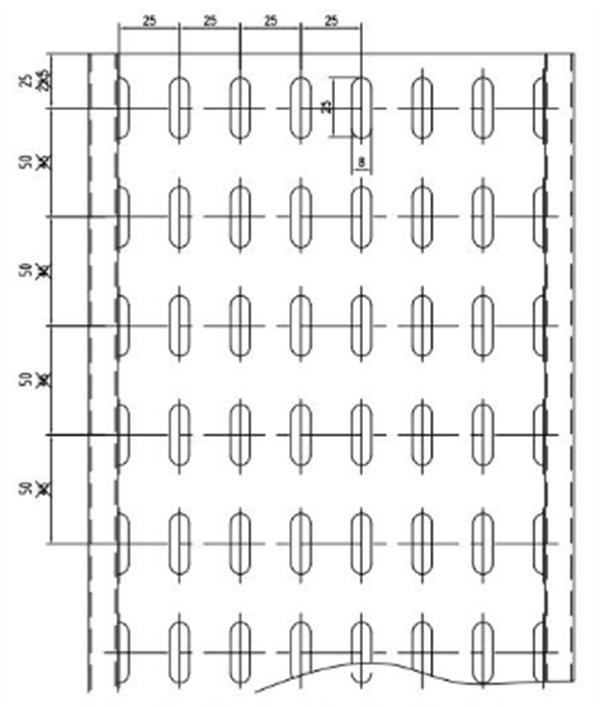

I. Profile Drawing:

Punching Details:

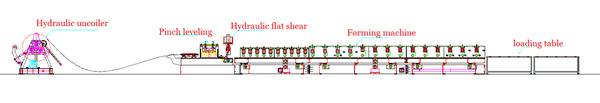

II. Process flow:

Passive uncoiling → Uncoiling and leveling two in one → Servo hydraulic punching → Forming machine → Length cutting → Unloading

III. Main Component data:

1. Uncoiler

(1) Uncoiler : Passive feeding, hydraulic expansion

(2) Loading Weight : 5T

(3) Uncoiler Coil I.D :508mm

(4) Rolling range : 450-540mm

(5) Uncoile power of hydraulic system : 3KW

(6) Uncoiler hydraulic system oil pump : blade pump

(7)2 roll pinch, 7 roll leveling

(8)Leveling roller Diameter : about φ 90mm

(9)Leveling roller material : quality 40Cr

(10)leveling shaft heat treatment : surface high-frequency quenching treatment

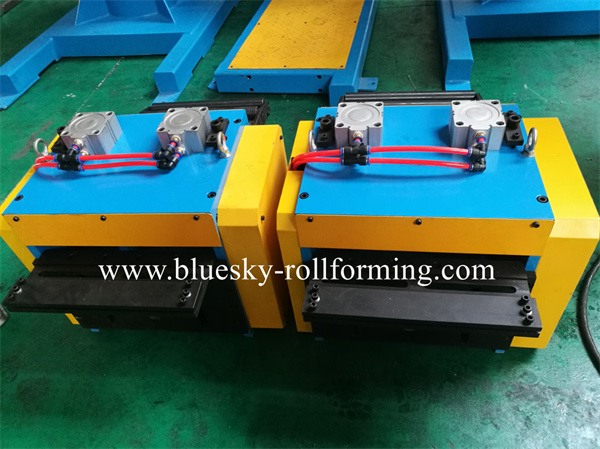

1. 1 Servo punching mechanism (hydraulic)

(1) Servo feeder power : 1.9kw

(2) Four - pillar hydraulic punching mechanism : single position

(3) Punching mould : 1 set

(4) Upper and lower template material : high quality 45 carbon steel

(5) Upper and lower die material : Cr12Mov or SDK11

(6) Hardness of upper and lower die heat treatment: HRC58-62

(7) Hydraulic system power : 15KW

(8)Hydraulic system cooling : air cooling

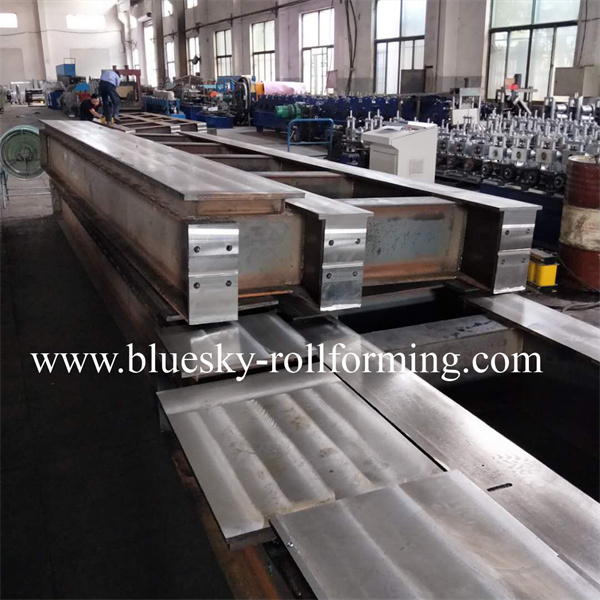

2. Roll Former

(1) main frame: High quality steel after welding and tempering

(2) Forming machine type: wall plate chain drive

(3) Shaft material : 40Cr

(4) Shaft diameter : Φ70 (HRB Bearing)

(5) Forming machine motor power : 15KW (Hardened surface reducer)

(6) Forming machine line speed : 0-15 m\min (excluding cut-off time)

(7) Roller way nos : 18nos

(8)Thickness : 0.8-2mm

(9)Length : ±1.5mm

(10)Roll material : Gcr15 quenching treatment (HRC58-62)

(11)Roll hard chromium plating acuity 0.05 mm

3. Hydraulic Shearer:

(1) Cutting type : hydraulic cutting off after forming (with scrap)

(2) Cutting blades : 1 pair

(3) Forming cut type material : Cr12M0V

(4) Heat treatment of cut blade : quenching treatment (HRC58-62)

(5) Motor power of hydraulic station : 7.5kw

(6) Hydraulic station oil pump : vane pump

5. Unloading table

(1) Unloading table size : 1500mm x 2 pcs

(2) Unloading table structure : Roller structure, angle steel welding, no power.

(3) Voltage:380v,50Hz,3ph( as per user)

IV. Equipment structure

The main machine is composed of Passive Uncoiler,Servo hydraulic punching mechanism, roller forming , hydraulic cutting mechanism, receiving mechanism, hydraulic system, electronic control system, etc。 :

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.8-2mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |