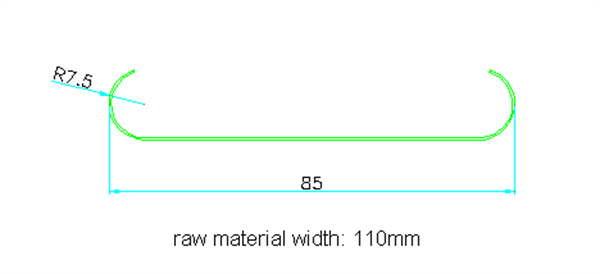

I. Profile: (according to confirmation by both parties)

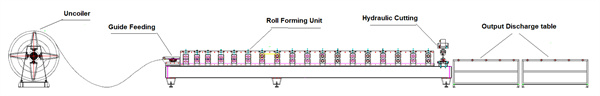

II. Process flow:

Passive unloading -----> Guide feeding ----> Roll forming ----> Cut to size

-----> Discharge table.

III. Main Component Data:

1. Suitable materials : Cold-rolled steel , Galvanized steel

2. Material thickness : 0.38 - 0.6 mm.

3. Material width : 110 mm.

4. Coil ID : 500 mm

5. Coil OD : 900 mm

6. loading weight :1000 KG

7. Forming speed : 0-30 m / min

8. Feeding accuracy : L≤3000mm ± 1.0 (related to material quality)

9. Straightness accuracy : L≤1000mm ± 2.0 (related to material quality)

10. Power supply voltage : 380 V, 50Hz, 3Ph

11. Feeding direction : As per user

12. Machine color : blue and orange red or as per buyer

13. Machine dimensions (L*W*H) : (4000*700*1600) mm

IV. Main components:

| Name | Model/name | Qty. | Instructions |

| 1. Single head material rack | ML-200 | 1 set | Passive uncoiling, manual expanding |

| 1. Main engine forming system | Feeding guide device | 1 set | horizontal direction |

| Horizontal rack | 10 Nos | Lower shaft active move while upper shaft passive move, roll forming between 2 side plates | |

| Cut-off system | 1 set | Auto cut to length, hydraulic shearing | |

| 2. Unloading table | 1 set | Equip simple products blanking frame | |

| 3. Electric control system | 1 set | PLC Control system |

V. Parameters of each component:

1. Uncoiling/leveling machine

(1) Function : single head

(2) Roll support : cantilever

(3) Unwinding method : passive

(4) Tightening method : mechanical linkage

(5) Loading Capacity : 1000KG

(6) Coil I.D : 500MM

(7) Coil O.D : 900MM

(8) Uncoiler power : no power

2. Roll Former

1) Frame: Welding the overall structure from profiled steel,Frame bottom plate thickness: 25mm

2) Standing house side panel:individual standing house,After finishing the surface is blackened; horizontal axis diameter φ38, key 12mm.

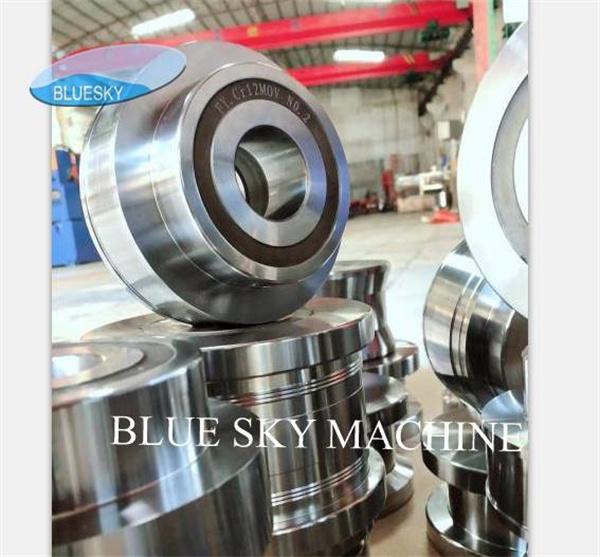

3) Roll material: S45C die steel, heat treatment: HRC58℃ after precision CNC processing, the surface of hard chromium plating polishing. Straightening and shaping: adopts single-channel stick-wheel structure, adjustable up, down, left and right.

4) Straightness: 5 rolls structure, both up & down, left & right can be adjusted to guarantee products straightness.

5) Forming method :cold bending forming

6) Roller way qty. : 12 NOS.

7) Forming machine form : from left to right or as per buyer

8) Forming speed : 0-30 m/min

9) Machine motor power : 4.0kw

10) Shearing motor power : 2.2 KW

3. Hydraulic cutting system

(1) With hydraulic as shearing power, hydraulic components from joint venture brand.

(2) Shearing method: auto shearing as per set parameter on the touch screen, blade material Cr12mov, quenched, HRC60℃.

4. Unloading table

(1) Material receiving roller size : 1200mm x 3000mm

(2) Structure : Independent agency

5. Electric control system

(1) Frequency control of motor speed control of main drive motor, Equipped with PLC programmable controller, Rotary encoder controls length.

(2) With 7 inch color touch screen, control mode: touch screen and button control.

(3) With a handheld controller

VI. Working environment:

Ø Environment temperature: -10℃~+40℃.

Ø Relative air humidity: no more than 60% when +40℃, and no more than 95% when +25℃.

Ø There is no material may cause explosion, nor gas that may corrode metal or damage insulating layer, and no conductive dust.

Ø No rains or snows.

Ø Power supply: voltage 380V±10%, 3-phase, frequency between 49.5-50.5 HZ

VII. Equipment structure composition:

The equipment host consists of a passive Unwinder, Roll forming host (including guided feeding, hydraulic cutting mechanism), a discharging platform, a hydraulic system, and an electronic control system.

The processing of equipment roll parts is completed by processing machinery such as CNC lathes, which effectively guarantees the machining accuracy of parts and components, and uses various process equipment and testing equipment to ensure the equipment assembly accuracy.

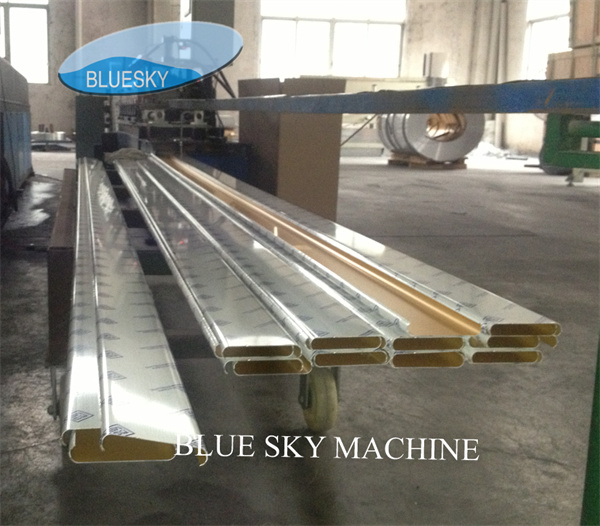

Finished product reference:

Machine picture:

| Raw Material | Type | Cold-rolled steel , Galvanized steel |

| Thickness | 0.38-0.6mm | |

| Performance | Speed | Max. 30m/min |

| Uncoiler | Type | Manual Expanding |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 12 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |