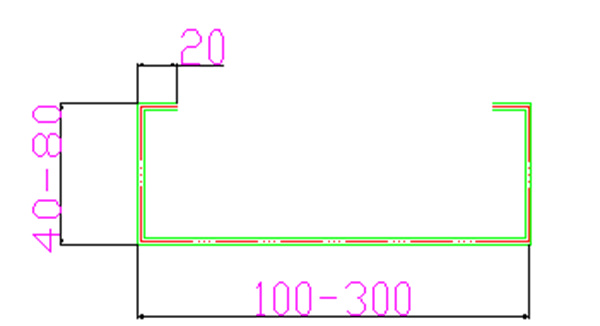

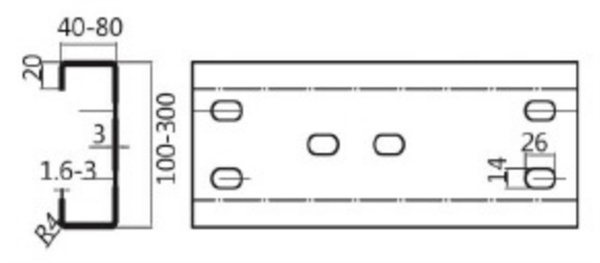

I. Profile drawing: (according to confirmation by both parties)

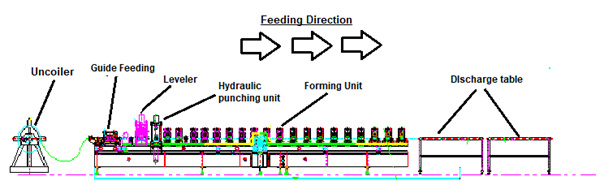

II. Process flow:

Decoiler -----> Guide feeding ------> Leveling and straighten ------> Hydraulic hole punching ------> Hydraulic cutting ------> Roll forming ------> Rectify rollers -----> Output discharge table.

III. Components of the Machine Line:

1. Uncoiler :

Manual Unwinder: 5 T

1) Structure of pedestal, braking, mandrel holder, slider narrow and expanding

Composition: base, braking device, hollow support, slider, tensioner

2) Capacity of Uncoiler : 5 ton (maximum load capacity of uncoiler: 5 T)

3) Max width : 500mm (maximum material width: 500mm)

4) Inner diameter for coil : Ф440mm-530mm (inner diameter of coil:

400mm-530mm)

5) Out diameter : Ф1500mm

2. Feeding guide & straighten device:

1) Hydraulic system for punching and pre-cutting device

2) Device for punching and front shearing

3) This device consisted by punching mould, cutting blade, oil cylinder and

hydraulic station (this device includes: 2 sets of punching dies, scissors, oil

cylinder, hydraulic station)

4) Pre-cutting before roll forming which no need to change cutting mould.

5) Material of punching and cutting blade: Cr12mov, quenched hardness 58 °

-62 ° (Material of punching and cutting blade: Cr12, quenching hardness

58 °-62 °)

6) Power for cutting: Hydraulic power 7.5KW.

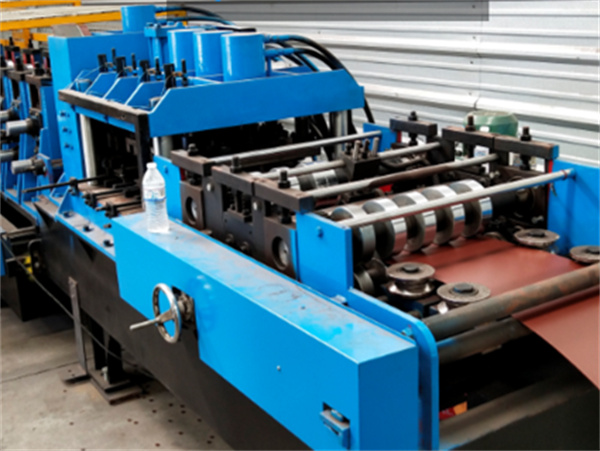

3. Roll Former:

1) Fit for raw material: Forming thickness 1.5-3.2mm, Q235, Q345 galvanized steel and hot rolled steel

2) Roll forming station : 17 stations

3) Rectify rollers : 3 stations

4) Diameter of roller shaft : Ф85mm (diameter of roller shaft: Ф85mm)

5) Material of roller shaft : 45 # steel

6) Roller material : Gcr15 bearing steel, forged and quenched hardness HRC58-62 ° (Roller material: bearing steel Grc15, forging and quenching hardness 58-62 °)

7) Roller process : CNC lathe processed

8) Motor for height adjusting: 2 * 0.75KW (power of height adjusting host: 2 * 0.75KW)

9) Motor for width adjusting : 1 * 1.5KW

10) Transmission : High strength Chain

11) Roll forming speed : 10-15m / min (not include punching & cutting time)

Forming speed : 10-15 m / min (excluding punching and cutting time)

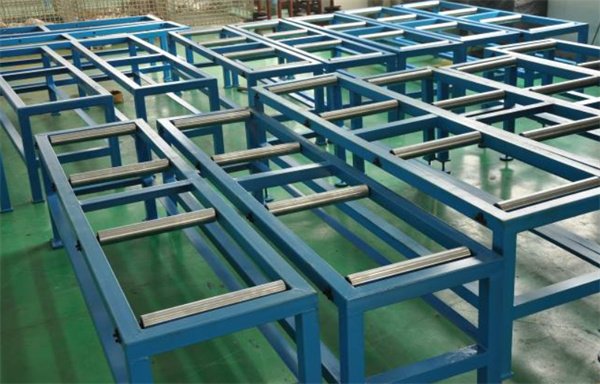

4. Unloading table:

1. Specification of unloading table: 3000mm x 2 pieces (to meet the

maximum specifications of profiles)

2. Unloading table structure: roller structure, square tube welding.

IV. Machine Picture:

Total Area for production line: 14m length x width 2.5m

Total weight will be about: 8T

| Raw Material | Type | Galvanized Sheet, Hot Rolled Steel |

| Thickness | 1.5-3.2 mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5 T | |

| Main Machine | Main Roller Station | 17 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |