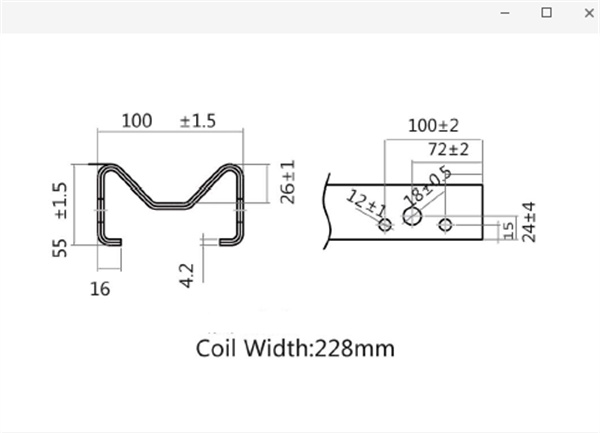

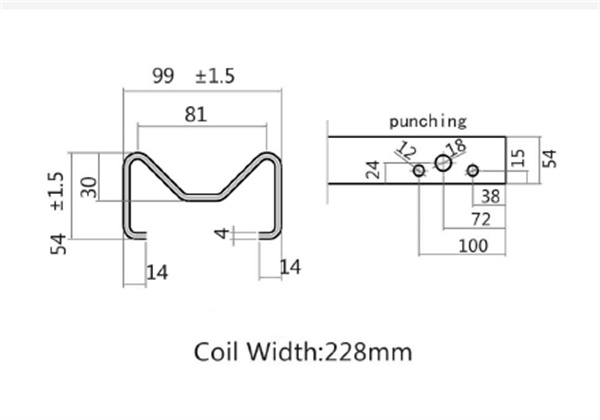

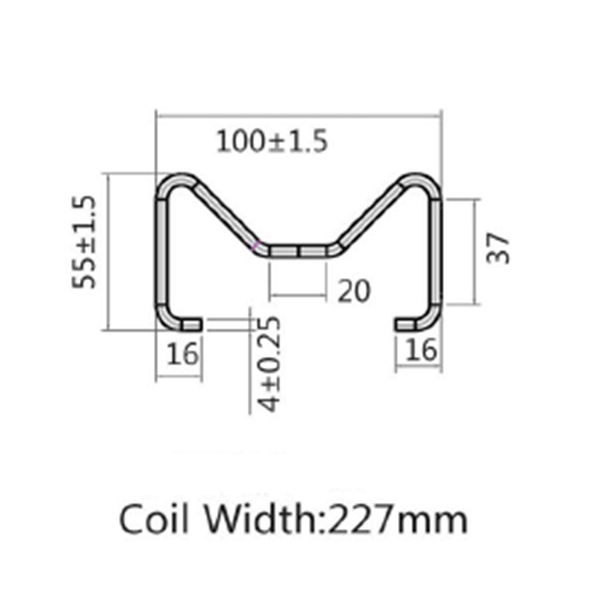

I. Profile drawing: (according to confirmation by both parties)

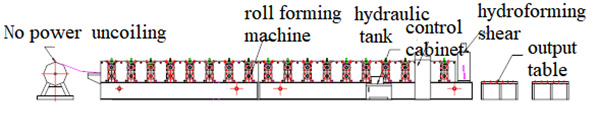

II. Process flow:

Automatic Unwinding -----> Guide feeding -----> Pinching and Leveling -----> Hydraulic punching -----> Roll forming -----> Hydraulic cutting -----> Output discharge table.

III. Main Component Data:

Technical parameters:

1. Uncoiler : automatic unwinding, hydraulic tensioning

2. Uncoiler load : 10T

3. Inner diameter of uncoiler : 508mm (can be customized according to

customer requirements)

4. Supporting roll range : 450-540mm

5. Motor power : 7.5kw

6. Frame: tempering treatment after welding of high-quality steel

7. Pinch feeding frame: side roller type

8. Leveling form: two rollers and seven rollers for leveling (upper 3,

lower 4 )

9. Feeding and leveling power : 7.5KW

10. Leveling roller shaft diameter : about 100mm

11. Leveling roller material : high quality 40Cr

12. Leveling shaft heat treatment : surface induction hardening

13. Leveling mechanism reducer : cycloid

14. Punching mold : 1 set

15. Material of upper and lower mold : Cr12MOV

16. Upper and lower die heat treatment : quenching HRC58-60

17. Forming machine form : Torii-type gearbox transmission (140 Torii +

Z180 gearbox)

18. Shaft material : 40Cr quenching and tempering treatment

(HB220-260)

19. Shaft diameter : Φ100 (Harbin bearing)

20. Motor power of forming machine : 37KW

21. Linear speed of forming machine : 0-10 meters \ min (excluding

punching and cutting time)

22. Number of forming lanes : 19 lanes

23. Thickness : 3.0-4.5mm

Material : Galvanized Coil (P52246-2004)

Tensile strength : 220-350mpa

24. Length : ± 1.5mm

25. Roll forming mold : 1 set

26. Blade material : Cr12mov (HRC58-62)

27. Shearing width : ≤500mm

28. Shear thickness : ≤ 5.0mm

29. Cut-off method : stop hydraulic cut-off

30. Hydraulic system power : 11KW

31. Hydraulic system oil pump : plunger pump

32. Hydraulic system with air cooling

33. Receiving rack transmission : passive

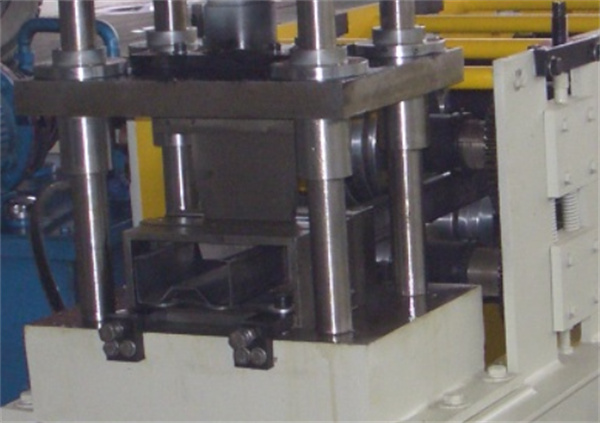

V. Machine Picture:

| Raw Material | Type | Galvanized Sheet |

| Thickness | 3-4.5mm | |

| Performance | Speed | Max.10m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 10T | |

| Main Machine | Main Roller Station | 16 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Gear Box | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |