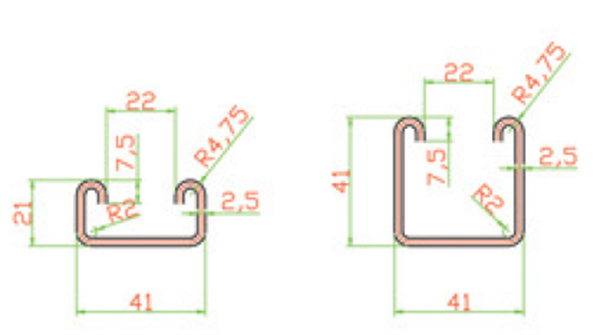

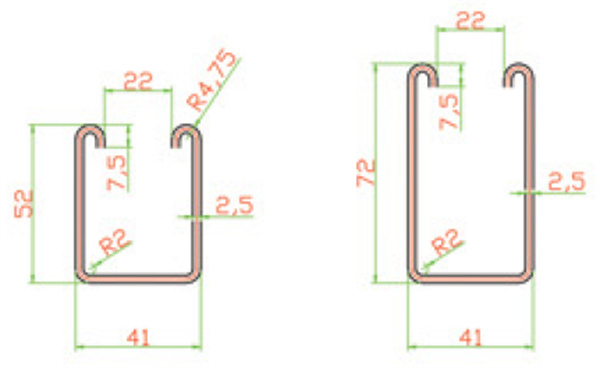

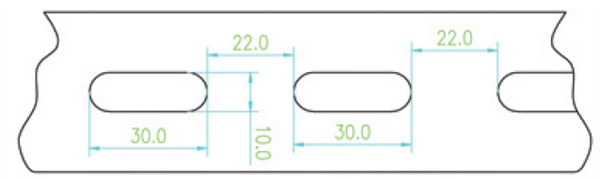

I. Profile Drawing:

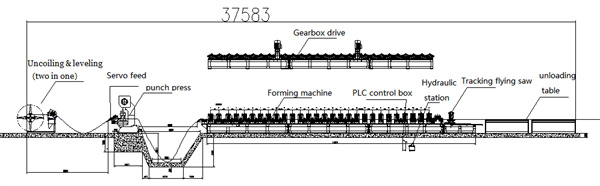

II. Process flow:

Passive uncoiling → Power leveling pinch → CN servo feed → 80T pneumatic punch press → forming machine → Hydraulic tracking and cutting → unloading

III. Main Component data:

1. Uncoiling & Leveling( two in one)

(1) Uncoiler Coil I.D. : ø 508 ± 30 mm

(2) Feeding width : 350mm

(3) Coil Max O.D. : ø 1500mm

(4) Max loading : 3T.

(5) Leveling roll: quantity : 7 rolls, material: 40Gr

(6) Leveling effective width : ≥300mm.

(7) Max leveling speed : 0-15m /min.

(8) Leveling power : 4 KW.

(9) Speed of auto induction line.

2. Punching system:

(1) Servo feeder

A. Servo feeder model : NCF - 300

B. Feeding width : 300mm

C. Coil thickness : 2.5mm

D. Feeding speed : 0-15m/min

E. Servo power : 2KW

(2) 80T pneumatic punch press : gantry type

(3) Mould material and process:

Punching hole mould, material : Cr12MoV, Quenching hardness: HRC: 58-62°.

3. Roll Former:

(1) Main frame : High quality steel after welding and tempering

(2) Forming machine type : Wall plate chain drive.

(3) Forming machine : standing house structure.

(4) Transmission mode : The forming roller is driven by 180 synchronous gearbox and motor reducer

(5) Coupling: between gear box and shaft head, direct coupling,Between the gearboxes, the sprocket coupling

(6) Shaft material : 40Cr quenching and tempering treatment (HB250-280)

(7) Roll material : Bearing steel GCr15

(8) Shaft diameter : Φ75 (HRB Bearing)

(9) Standing house : Material: Ductile iron. Specifications: 500× 300 × 60mm. CNC finishing

(10) Bearing block : cast iron, finishing, double bearing structure.

(11) Circulating cooling system

(12) Forming speed : 0-15 m/min.

(13) Forming machine motor power: 22 KW

(14) Roller way nos : 28 nos

(15) Thickness : 1.2-2.5 mm (Cold Rolled Steel, SS, HR Steel.)

(16) Raw material width : width of the actual test plate shall prevail

(17) Feeding action size : 300mm

4. Cutting Mechanism (Tracking non-stop hydraulic punching and cutting)

(1) Cutting type : Hydraulic punching and cutting

(2) Tracking type : Mechanical tracking, pneumatic return stroke, set buffer cylinder to ensure a stable return stroke

(3) Forming cut type material : Cr12M0V,CNC line cutting, fine grinding

(4) Cutting blade : 5 sets

(5) Heat treatment of cut blade : quenching treatment (HRC58-62)

(6) Hydraulic system power : 4 KW

(7) Hydraulic power : 5.5 KW

(8) Cutting thickness : 2.5 mm

5. Unloading table

(1) Unloading table size :1500mm

(2) Receiving table structure : Roller structure, angle steel welding, no power.

6. Electric control system

(1) Voltage : 415V, 50Hz,3 phase.

| Raw Material | Type | Cold Rolled Steel, SS, HR Steel |

| Thickness | 1.2-2.5mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Gear Box | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |