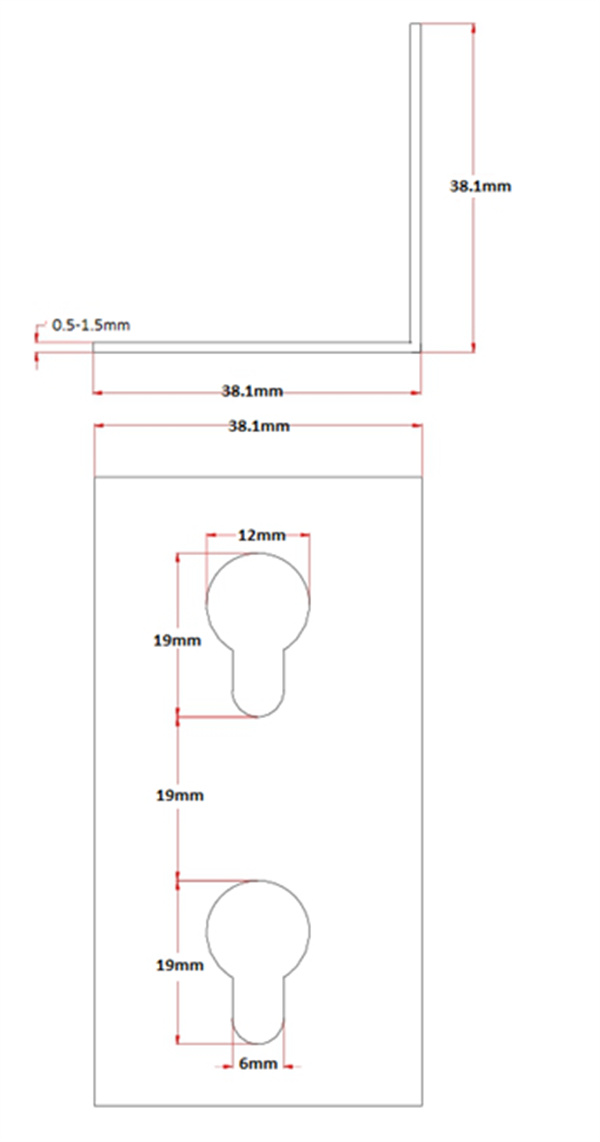

I. ‘L’ Angle Profile: (according to confirmation by both parties)

Physical display drawing:

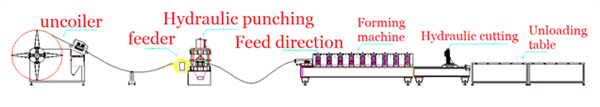

II. Process flow:

Passive uncoiling (Uncoiling and leveling two in one) → Servo hydraulic punching → Forming machine → Length cutting → Unloading

III.Machine Components in detail:

1. Uncoiler

(1) Uncoiler : Passive feeding, hydraulic expansion

(2) Loading Weight : 5T

(3) Uncoiler Coil I. D : 508mm

(4) Rolling range : 450-530mm

(5) Hydraulic uncoiler system power : 1.5kw

(6) Hydraulic pump uncoiler system : gear pump or a vane pump

(7) Leveling mechanism structure : 2-roller pinch, 7-roller

leveling

(8) Leveling roller shaft diameter : about φ52.5mm

(9) Leveling roller material : high quality 40Cr

(10) Flattening shaft heat treatment method: surface high frequency quenching treatment

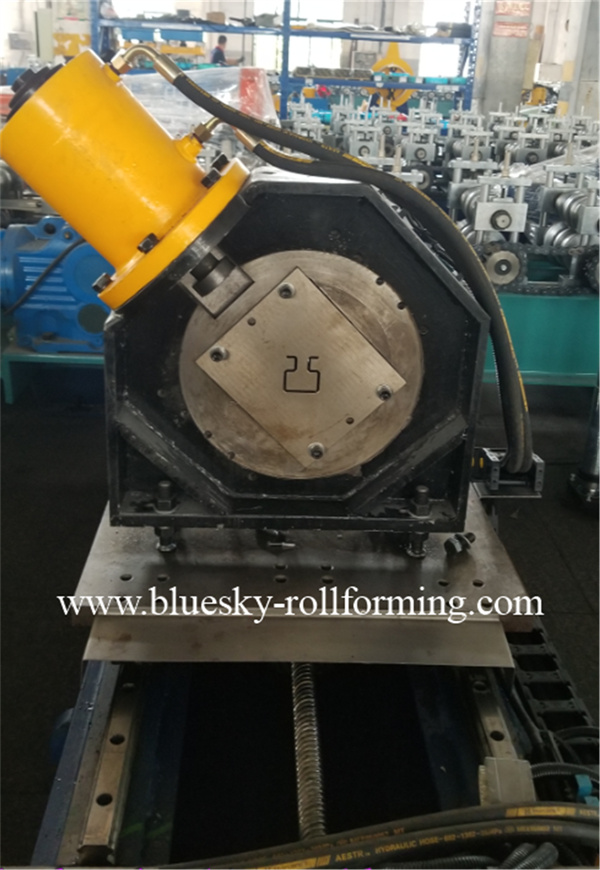

1. Servo punching mechanism (hydraulic):

(1) Servo feeder power : 1.9kw

(2) Four - pillar hydraulic punching mechanism : single position

(3) Punching die : 1 set

(4) Upper and lower template material : high quality 45#carbon steel

(5) Upper and lower die material : Cr12Mov or SDK11

(7) Hardness of upper and lower die heat treatment : HRC58-62

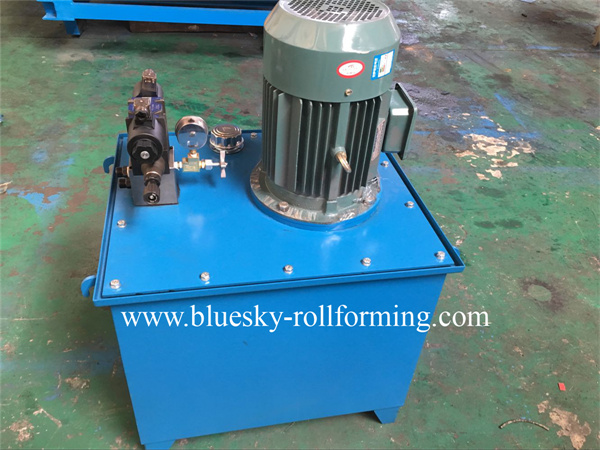

(8) Hydraulic system power : 11KW (single circuit)

(9) Hydraulic system solenoid valve : BEIJING HUADE

(10) Hydraulic system cooling : air cooling

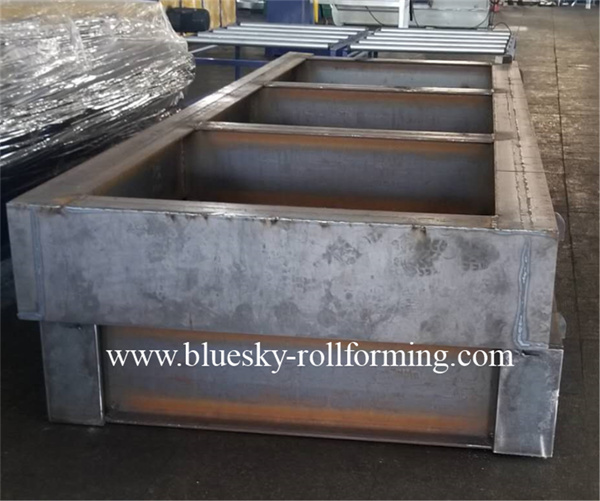

2. Roll Former:

(1) Main frame: High quality steel after welding and tempering

(2) Forming machine type: wall plate chain drive

(3) Shaft material: 40Cr quenching and tempering treatment (HB220-260)

(4) Shaft diameter : Φ70 (HRB Bearing)

(6) Forming machine motor power : 7.5KW (hard surface reducer)

(7) Forming machine line speed : 0-15m\min

(8) Roller way nos : 8 Nos (plus three roller regulate)

(9) Thickness : 0.5-1.5mm (stainless steel, cold rolled steel)

(10) Expanded width of rolled material: based on the actual test plate width

(11) Length limit : ±1.5mm

(12) Roll material : Ccr15 quenching treatment (HRC58-62)

(13) Roll hard chrome plating : ≥ 0.05mm

3. Hydraulic cutting(Servo tracking):

(1) Cutting type : after molding stop hydraulic cut off

(2) Cutting blade : 1 Pay.

(3) Forming cutting mold material : Cr12M0V

(4) Heat treatment of cutting blade : quenching treatment (HRC58-62)

(5) Motor power of hydraulic station : 4kw

(7) Hydraulic station oil pump : vane pump

4. Unloading Table:

(1) Structure of receiving roller : Angle welding, drum type (no power)

(2) Material receiving roller size : 1500mmx2pcs

(3)Voltage : 415v,50Hz,3ph

IV、Equipment structure:

The main machine is composed of passive Uncoiler, Servo hydraulic punching mechanism, Roller forming machine, hydraulic cutting mechanism, material receiving mechanism, hydraulic system, electronic control system, etc.

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.5-1.5mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 5T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |