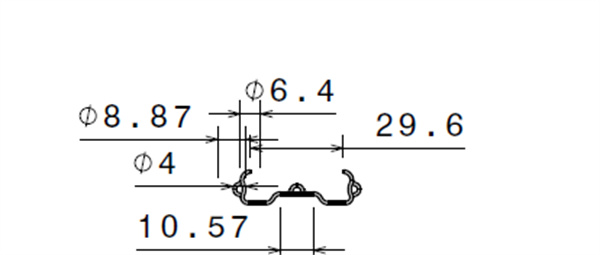

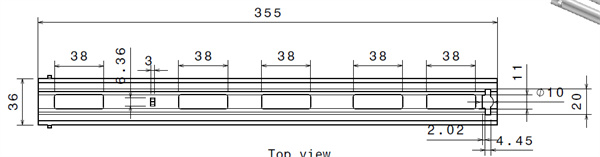

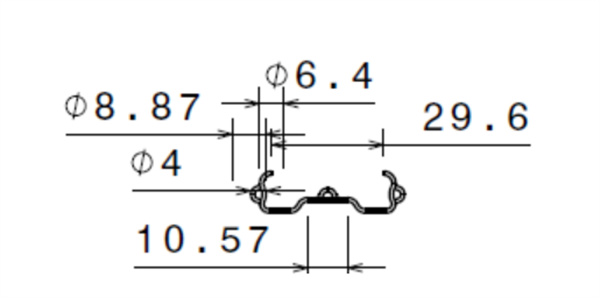

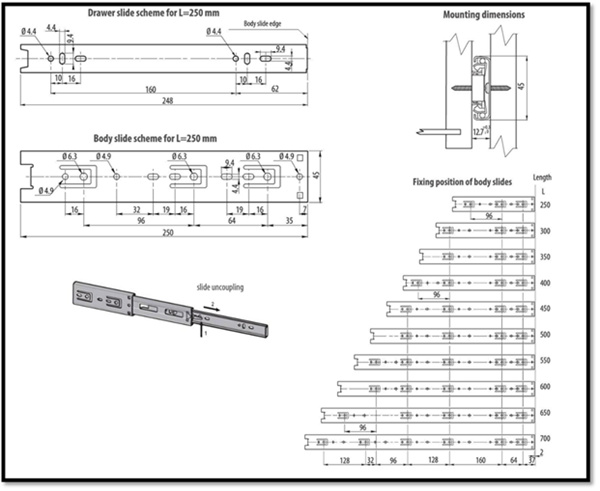

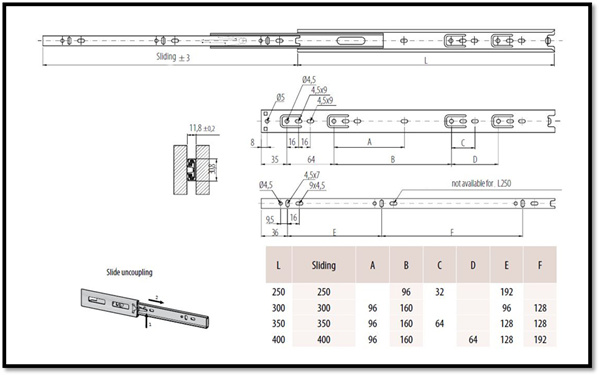

I. Profile Drawing: (according to confirmation by both parties)

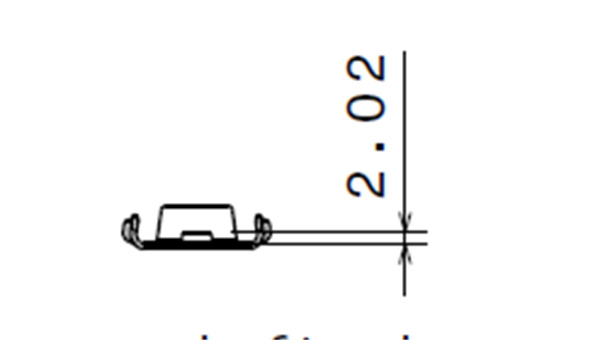

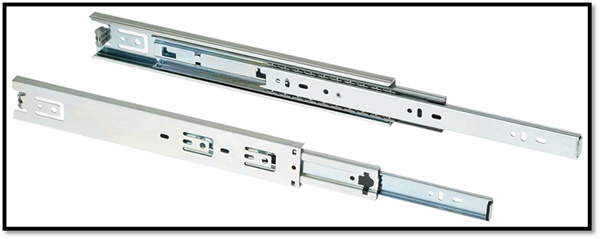

Inner Drawer Rail Machine:

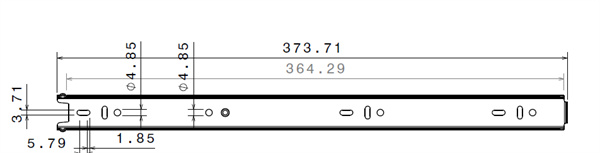

Outer Drawer Rail Machine:

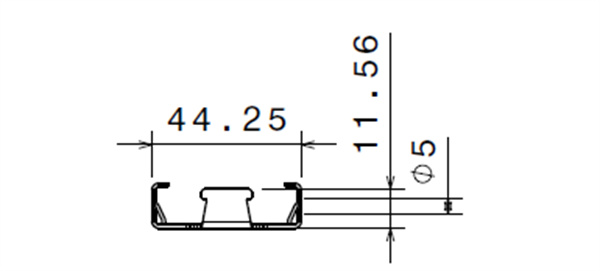

Middle Sliding drawer rail machine:

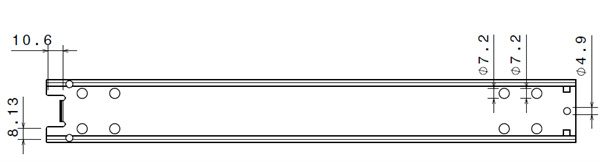

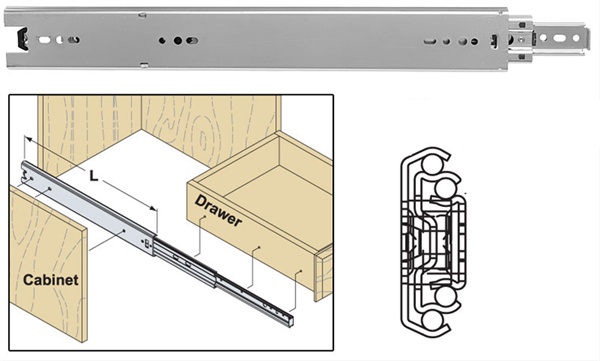

ASSEMBLED DRAWING:

Note: Product thickness range from 0.8 mm to 1.2 mm can be produced

II. Process flow:

Manual Decoiler ------> Feeding Device ------> Roller Forming Machine ------> Holes punching Device -----> Length cutting ------> Product Tables -------> Holes punching ,bend ------> End cut -----> Bent Device (outside the line)

III. Main Machine Components:

| S No. | Item | Quantity |

| 1. | De-coiler (3 T – Manual) | 1 Set |

| 2. | Feeding Device | 1 Set |

| 3. | Roller Forming Equipment | 12 stands |

| 4. | Encoder | 1 Set |

| 5. | Holes punching Device (in line) | 1 Set |

| 6. | PLC Control cabinet | 1 Set |

| 7. | Product Table | 2 pcs |

| 8. | Punching dies (to be done outside the line) | 3 sets |

| 9. | Hydraulic station | 1 Set

|

VI、Main Technical Parameter:

1. Product Info

(1) Suitable Material : Carbon steel

(2) Material Thickness : 1.2 mm

(3) Yield Strength : Normal Strength

(4) Product Size : per the drawing

2. De-coiler Specs

(1) Type : Manual Cantilever Type

(2) Max Loading Weight : 3 T

(3) Coil ID : Φ508 mm

(4) Coil OD : ≤1200 mm

3. Roller Forming Equipment Specs

(1) Machine Stations : 12 stands

(2) Forming Speed : 12-15 m/Min (Not included cutting time)

(3) Roller Material : Cr12Mov,HRC58-62,Hard chrome-plated,

(4) Shaft Diameter : Φ60 mm

(5) Shaft Material : 40Cr, milling

(6) Machine Structure : Iron stands

(7) Main Body Frame : H-beam Steel Welding Structure

(8) Transmission Type : Worm gearbox drive

(9) Main Motor Power : 15 KW

(10) Cutting Type : Hydraulic cutting

(11) Cutting Power : 11 KW

(12) Cutting Tolerance : ±0.5 mm

(13) Width tolerance : +/-0.2 mm

(14) Forming Machine Dimension : About 6.5M*0.8M*1.3M

(15) Machine Total Weight : About 4 MT

(16) Machine Paint : Blue-Yellow

4. PLC control cabinet

(1) Touch Screen : 7inch

(2) Aviation Plugs

5. Unloading Table

Dimension : 500 mm x 0.4 m x 1.4 m (2 Pcs)

Continuous Line of The Decoiler, Leveller, Servo-feeder and Punching press

Flowchart:

Motorized decoiler ------> Powered leveling ------> Servo feeder -----> Punching mould and Punching press (the punching press is offered by the buyer) ------> Outable

1. Motorized Decoiler:

(1) Width of material : (max) 150mm

(2) Manual inner expansion and motorized decoiling

(3) Motor : 4 KW

(4) Inner diameter of coil : φ508 mm

(5) Inner expansion range : ф460-520 mm

(6) Outer max. diameter : φ1500 mm

(7) Max. loading capacity : ≤3 T

2. Leveller:

(1) We adopt 2 pinch rolls and 7 rolls leveling (upper 3 rolls and bottom 4 rolls)

(2) Pinch rolls and leveling rolls material : 40Cr

(3) Leveling rolls width : max 150mm

(4) Materials thickness : (0.5--2) mm steel grade G350Mpa

(5) Motor power : 5.5kw

(6) Way of drive : Gear drive

(7) Upper leveling rolls is adjusted by the screw rod with measures meter

(8) The press botton “start” and “stop”

(9) Voltage requirements : 380V, 50Hz, 3Phase.

3. Servo-feeder model:SRF-100A:

(1) Function : For material feeding into the press punching machine

(2) Feature : Uses the servo motor-driven.

(3) Feeding capability : Width 1 00mm x 0.2-1.2mm coils

(4) Feeding speed : 20 m/min (max)

(5) Feeding accuracy : ≤±0.1mm (within 100mm) ≤±0.2mm (within 500mm)

(6) Max feeding step distance : ≤ 9999.99 mm

(7) It will be installed on the side of the pressing machine.

4. Punching press machine:

(1) Model of punching press : JH21-80

(2) Punching press : Uses the steel plate welding fuselage, the rigidity is strong with good appearance.

(3) Uses the combined type air operated friction clutch.

(4) Punched 45 times per min

(5) Worktable size : 900mm

(6) Worktable thickness : 130mm

(7) Motor power : 11kw

(8) Weight : 5,000kgs

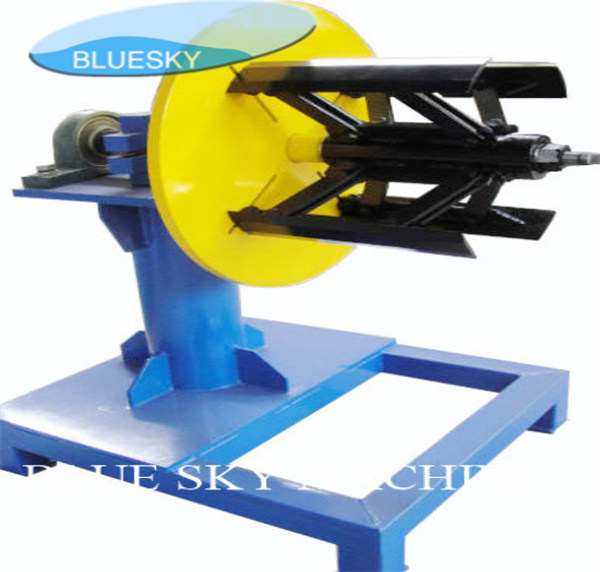

Machine Pictures:

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.5-2mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Manual Cantilever Type |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 12 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Gear box | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |