I. Profile: (according to confirmation by both parties)

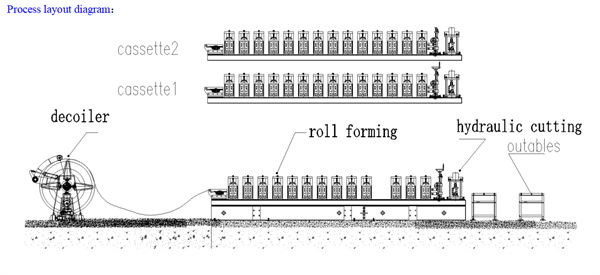

II. Process flow:

Uncoiling (Passive) ------> Guide Feeding -----> Roll Forming -----> Hydraulic cutting ------> Unloading (Discharge table / Outable).

III. Main Technical data:

1. Uncoiler

(1) Uncoiler : Passive feeding, Manual expansion

(2) Loading Weight : 3 T

(3) Uncoiler Coil I. D : 508 mm

2. Roll forming machine

(1) Main frame : High quality steel after welding and tempering

(2) Forming machine type: Lifting quick change type (changing the forming frame with different specifications)

(3) Shaft material : 40Cr quenching and tempering treatment (HB220-260)

(4) Transmission mode : chain transmission

(5) Shaft diameter : Φ65 (HRB Bearing)

(6) Forming machine motor power : 11 KW (Hardened surface reducer)

(7) Forming machine line speed : 0-15 m/min

(8) Roller way nos : 24 Nos(Add a series of vertical rollers)

(9)Thickness : 0.5 - 0.8 mm (GI coated strip)

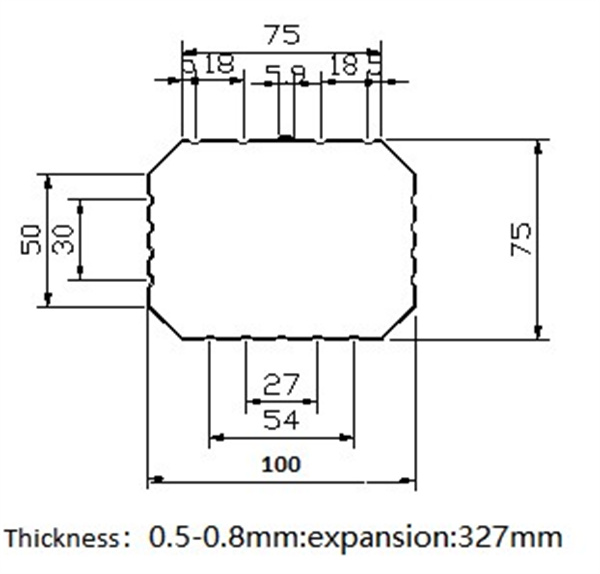

(10) Raw material width : For profile (100*75) - 327mm;

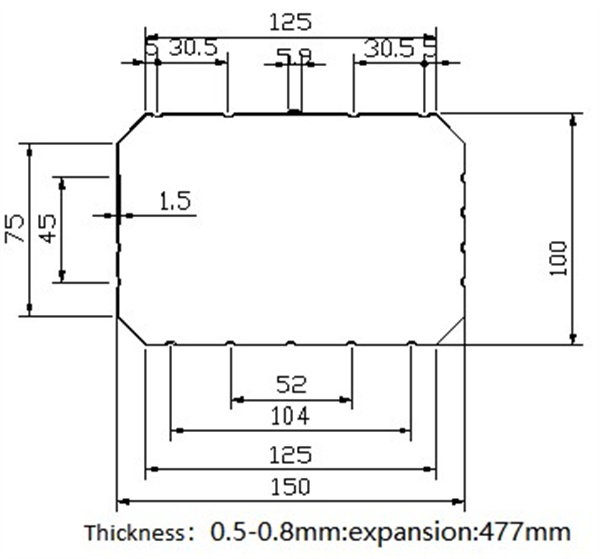

For profile (150*100) - 477mm;

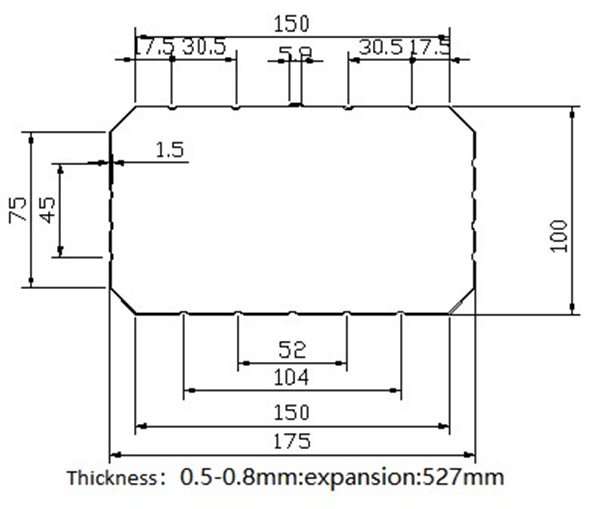

For Profile (175*100) – 527mm

(11) Length tolerance : ±1.5 mm

(12) Roll material : High quality carbon steel tempering treatment (HB220-260)

(13) Roll hard chrome coating ≥ 0.05mm

3. Cutting mechanism

(1) Cutting type : After forming stop hydraulic cutting

(2) Forming cut type material : Cr12M0V

(3) Heat treatment of cut blade : quenching treatment (HRC58-62)

(4) Hydraulic system power : 3 KW

(5) Hydraulic station oil pump: Vane pump

4. Unloading table

(1) Unloading table size : 2000mm x 2 pcs

(2) Unloading table structure : Roller structure, angle steel welding, no power.

IV. Equipment structure:

The main machine is composed of Passive Uncoiler, roll forming (Including Guide feed, disc saw cut), loading table, electronic control system, etc.

V. Pipe bender: (Optional)

Equipment data:

1. Control mode : Hydraulic control

2. Hydraulic power : 3 KW

3. Max bending angle : 90 degrees

4. Auxiliary function : with shrinkage function

5. Bending machine size (mm) : 1200x650x1500

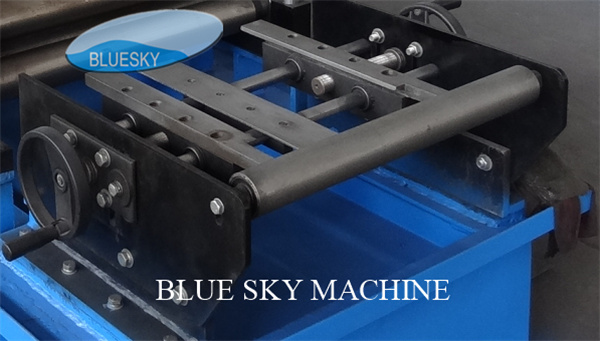

Product Pictures:

| Raw Material | Type | Galvanized Sheet |

| Thickness | 0.5-0.8mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Hydraulic |

| Capacity | 3 T | |

| Main Machine | Main Roller Station | 24 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |