I. Profile drawing: (according to confirmation by both parties)

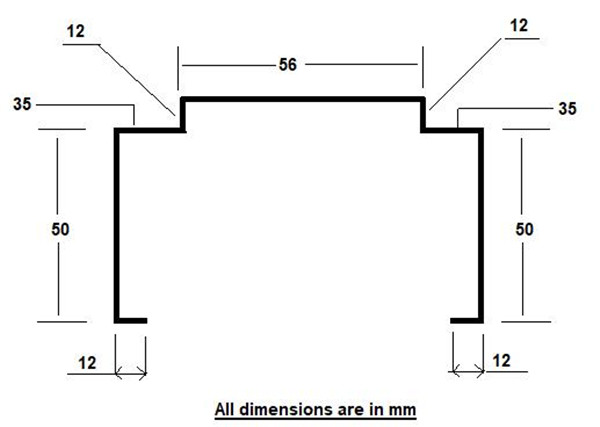

PROFILE – 1:

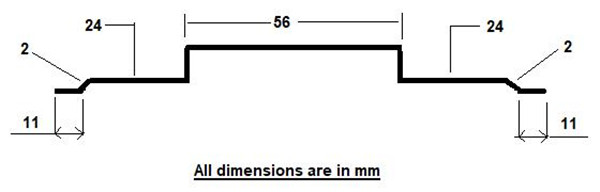

PROFILE – 2:

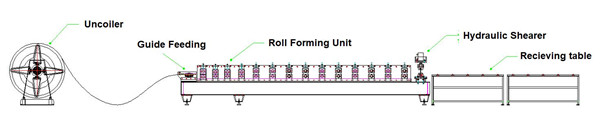

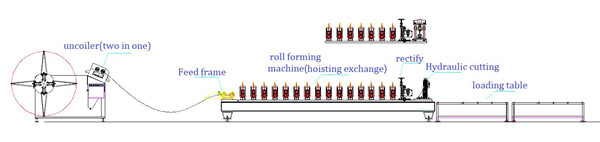

II. Process flow:

Passive unloading -----> Guide Feeding -----> Roll forming -----> Hydraulic Shearing -----> Discharge table.

III. Machine Component details:

1. Uncoiler:

1) Uncoiler: Passive feeding, manual expansion

2) Loading Weight : 5T

3) Uncoiler Coil I. D: 508mm

4) Rolling range: 450-530mm

5) Uncoiler electrical control system : main electrical components adopt well-known brands

6) 2 roll pinch, 7 roll leveling

7) Leveling roller Diameter : about φ 52.5mm

8) Leveling roller material: quality 40Cr

9) Leveling shaft heat treatment: surface high-frequency quenching treatment

2. Forming Machine:

1) Main frame: High quality steel after welding and tempering

2) Forming machine type : cast iron standing house chain drive(Hoisting exchange),exchange diagram

3) Shaft material: 40Cr

4) Shaft diameter: Φ70 (HRB Bearing)

5) Motor power: 11KW (Hardened surface reducer)

6) Forming machine line speed: 0-15 m\min (excluding cut-off time)

7) Roller way nos: Hoisting the corresponding unit when producing different size:

Profile 1: roller way nos: 15 Nos (plus rectify mechanism)

Profile 2: roller way nos: 7 Nos (plus rectify mechanism)

8) Rolling thickness: 1.5-2.0mm (CR Sheets, MS)

9) Expanded width of rolled material : The actual width of the test plate shall prevail

10) Length Accuracy : ±1mm

11) Roll material: Gcr15

12 ) Roll hard chromium plating acuity 0.05 mm

Schematic diagram of unit (Roll Cassette) change:

(Picture is for reference only, subject to actual design)

3. Hydraulic cutting mechanism: (When cutting different profiles, exchange with the forming unit, share the hydraulic system)

Profile 1:

(1) Cutting type:45° hydraulic cutting after forming (no scrap)

(2) Cutting blades: 1 pair

(3) Forming cut type material: Cr12M0V

(4) Heat treatment of cut blade: quenching treatment (HRC58-62)

Profile 2:

(1) Cutting type : Hydraulic cut off after forming (with scrap)

(2) Cutting blades : 1 pair

(3) Forming cut type material : Cr12M0V

(4) Heat treatment of cut blade : quenching treatment (HRC58-62)

(5) Motor power of hydraulic station: 5.5kw

(6) Hydraulic station oil pump: vane pump

4. Unloading table

(1)Unloading table size: 2000mm * 2 pcs

(2)Unloading table structure : Roller structure, angle steel welding, no power.

IV. Equipment structure

The main machine is composed of Passive Uncoiler roller forming (Including guide feeding, hydraulic cutting mechanism), loading platform ,hydraulic system, electronic control system, etc.

| Raw Material | Type | Galvanized Sheet |

| Thickness | 1.5-2.0mm | |

| Performance | Speed | Max. 15m/min |

| Uncoiler | Type | Manual expansion |

| Capacity | 5 T | |

| Main Machine | Main Roller Station | 7 |

| Main Drive | Hydraulic Motor or Servo Motor | |

| Transmission Type | Chain | |

| Cutting | Cutter Type | Hydraulic |

| Cutter Material | Cr12 |