We,Guangzhou Blue Sky sincerely invite you to the Tube Düsseldorf in Messe Duesseldorf Stockumer Kirchstr. 61, 40474 Duesseldorf, Germany from April 15th to 19th, 2024.

I'm excited for the opportunity to explore world-class innovation technology in the cut to length line, slitting line and tube mills.We expect to see you at Hall 6, Stall 6I32.

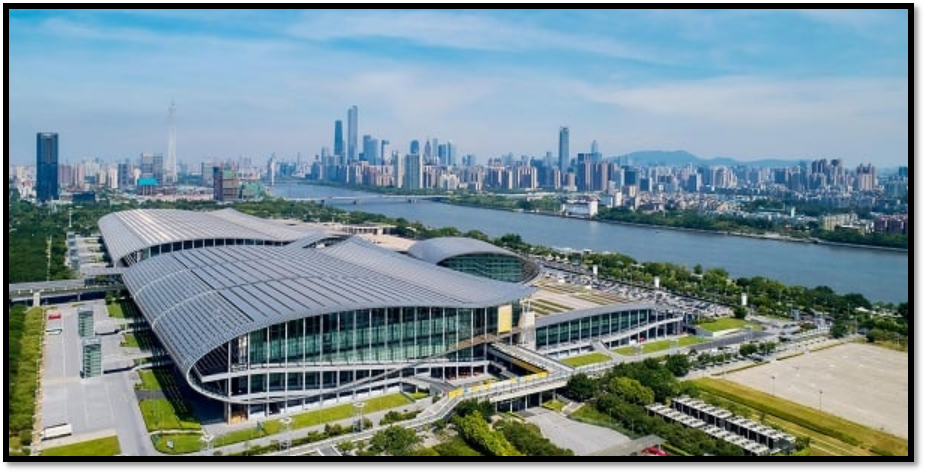

Guangzhou Blue Sky Machine Co Ltd will be participating in the 135th Canton Fair, also known as the China Import and Export Fair, which is scheduled to take place from April 15th to 19th, 2024, at the China Import and Export Fair Complex in Pazhou Island, Guangzhou, China, Our Stall is 19.1L16. This complex is also known as the Guangzhou International Convention & Exhibition Centre or Pazhou International Exhibition Center and is the largest modernized exhibition center in Asia.

We are excited to extend this invitation to you to visit us and explore the latest state-of-the-art technology equipment for Metal Strip Processing, including Slitting Lines, Cut to Length lines, Tube Mills, etc. Please mark your calendar for the dates from 15th to 19th April 2024, and plan your visa and travel arrangements accordingly. We look forward to your visit and the opportunity to showcase our innovative technology firsthand. Thank you for your consideration, and we hope to see you soon.

Your presence will be highly appreciated and our team is excited to welcome you to our booth 19.1L16. Please do visit us!

Combined with the production process of slitting lines, the site can be divided into several processing areas, namely feeding area, slitting area and edge scrap winding area. Among them, the length of the feeding area of the slitting line is about 4m, the slitting area is about 10m, and the edge scrap winding area is used to wind the edge scrap on the floor, which will be moved to the hoisting hole through the scrap sliding groove, and then lifted out by the crane.

Characteristics of Installation

In order to ensure that the steel slitting line actual production requirements are met, the installation accuracy required by the drawing design is relatively high, and the quality requirements of the slitting machine equipment are high, so the relative requirements for construction technology are also high, and it is necessary to be familiar with various technical data, the installation and commissioning tools and instruments.

Construction Layout:

Considering the limited installation space on site, the arrangement of the slitting line is relatively compact. Therefore, the reasonable allocation of equipment and construction land occupation should be fully considered in the construction division. In addition, the construction site should be fenced with colored strip cloth to avoid affecting the lines in production. At the same time, combined with the conditions of the site, a temporary warehouse can be arranged around the site for storing wearing parts, and the specific location of the warehouse is specified by the owner and uniformly arranged according to the actual situation of the site. Most of the slitting equipment should be installed with the unpacked, reducing the occupation time as much as possible and improving the efficiency of the equipment occupation.

After the slitting line is unpacked and inspected, its basic condition should be checked together with the on-site management personnel for any possible damage or missing part. After confirmation, it will be sent directly to the construction operation point and arranged in order to facilitate the smooth implementation of the installation.

"Metalogic Conference on Steel Service Center, Retailing & Distribution on 20th December 2022 at Hotel Tip Top International, Pune, India." We, GUANGZHOU BLUE SKY MACHINE CO LTD will participate in Metalogic Conference Event on 20th Dec'22 in Pune (India), our Stall No is 2.

The conference focuses on the current status of steel service and their future prospects, the importance and need of digitization. Focus on adoption of relevant information technologies with appropriate linkages to physical distribution chains to service the complex market dynamics can yield significant business returns for steel players. The steel industry needs to evaluate the digital disruption taking place in other industries and how some of the challenges can be mitigated by using emerging technologies.

All Steel Retailers, distributors, Steel Service Center companies will be participating in this event. We, Guangzhou Blue Sky Machine Co Ltd also participating in this. We have a well-equipped and professional factory with the latest technology. Offer a wide range of sheet metal equipment and production lines. Cut to length line, Slitting lines, Roll forming machine, Tube Mill, supplying both machines and solutions.

We We are looking forward to see you at our Stall 2, Metalogic Conference on Steel Service Center at Hotel Tip Top International, Pune.

1. Is cut to length line common and commonly used in metal processing?

In metal processing, the cut to length line can be a common and commonly used processing equipment, which is used to uncoil, level and cut the metal sheets, so as to achieve the processing purpose and obtain the desired processing effect.

2. Can the manufacturer of the cut to length line have other products?

The main product of the manufacturer of the CTL Production is Cut to Length Line, but this does not mean that the manufacturer only has the product ofcut to length line; Instead, the manufacturer can also have other products, such as uncoiler, bending machine and leveler, which can allow buyers to have a variety of different choices and meet different purchase needs.

3. Does the sheet metal industry need to use cut to length line?

Coil cut to length line, from a professional point of view, is a series of processing operations such as uncoiling, leveling and shearing of metal sheets, which can be specially used to process cold-rolled coils and hot-rolled coils, so the sheet metal industry needs to use cut to length line, especially in the combination of uncoiling, leveling and shearing.

4. Is thin sheet cut to length line used to process cold-rolled coil or hot-rolled coil?

Thin Coil Cut To Length Line is a specific type of cut to length lines, which is used to process cold-rolled coils with a thickness of 0.3-3mm in application. Moreover, the processing width of this type of equipment is possible to reach 1300mm in the pass. But with the continuous advancement of science and technology, it can now reach 1500mm.

Slitting line, also known as slitter and slitting machine, is a name for metal slitting equipment. It is suitable for longitudinal shearing of metal strips and recoiling the narrow strips after slitted into coils. It has the characteristics of easy operation, high cutting quality, high material utilization and stepless speed regulation.

The main components of the hydraulic system of the Slitting Production Line adopt high-precision components, the electrical control adopts imported PLC program controller and touch screen for the whole line of function control; One-key coil loading guarantees the smooth completion of each process, effectively reduce the labor intensity of workers, and has a high cost performance; It is a high-performance product integrating machine, electricity and hydraulics.

Using finite element analysis method, computer-aided optimization design, the product design structure is reasonable. The overall body structure is made of welded steel plates, with the use of aging heat treatment to eliminate the stress in the frame, it has good strength, rigidity, vibration resistance and long service life.

The manufacturing process of the whole Slitting Machine is strictly in accordance with the design specifications of the machine, and the machine body adopts CNC floor-type boring and milling machine for one-time processing and forming to ensure the parallelism and perpendicularity of each installation surface. With the experience of material selection, the processing technology is complete and reasonable, effectively improve the product accuracy and precision retention.

The whole frame is de-rusted and sprayed with anti-rust paint, and the painted color is long-lasting and bright. Working shafts of the whole machine adopts heavy-duty bearings and advanced lubrication system, which has a long service life.

The motor control system basically adopts weak current control to ensure the safety of the operator. It has high degree of automation, convenient and simple operation, upper and lower working roller clearance can be adjusted quickly through the motor, effectively shorten the auxiliary time and improve high efficiency.

Cut to length line is used to uncoil, level, measure and cut metal sheet coils to flat sheets in required length and stack the products to piles. It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and various metal materials with surface coating.

Structure Composition of Cut to Length Line:

Cut to length line is mainly composed of loading coil car, uncoiler, leveler, pinch feeding mechanism, shear, conveyor and stacker. The production line can be equipped with a slitter to slit metal sheets to the required width, then cut them to a required length and stack the products. It is a high-performance product integrating machine, electricity and hydraulics. It has high degree of automation with simple and reliable operation. It has high length accuracy, good leveling effect on metal sheets and neat stacking.

Slitting line, also known as slitting unit, slitting machine, etc., is mainly used to process tinplate, galvanized iron, silicon steel sheet, cold-rolled strip, stainless steel strip, aluminum strip, steel strip and other metal coils. It is necessary equipment for precision slitting of metal coils into strips of various widths required and then recoil the strips into small coils for the next process.

Suitable Industries:

Mainly used in transformers, motors, home appliances, automobiles, building materials, packaging industries, etc.

Process Flow:

Loading - Uncoiler - Pinching - Looping - Slitting - Edge Scrap Winding - Conveying - Tensioning - Recoiling - Unloading (Hydraulic System + Electrical Control System + Pneumatic System)

Specifically, th process flow of a typical Slitting Line includes: Loading Coil Car - Uncoiler - Snubber Roll - Pinching Leveler - Entry Shear - 1# Loop Bridge - Side Guide - Slitter - Edge Scrap Winders - Conveyor - 2# Loop Bridge - Pre-separator - Tensioner - Pinch Roll - Parting Shear - Deflector Roll - Rear Bridge - Recoiler - Unloading Coil Car - Rear Support Arm - Hydraulic System - Electrical Control System

EuroBLECH Sheet Metal Technology Exhibition in HANOVER, GERMANY from 25th-28th October’2022 is going on. Welcome to our Hall at 13 HALL, STALL NO. D184E

We, Blue Sky Machine, as a leading manufacturer of Sheet Metal Equipment and Production Lines. Cut to length line, Slitting line, Tube Mill and Roll Forming Machine. We are at 13 HALL, STALL NO. D184E for you.

GUANGZHOU BLUE SKY MACHINE CO LTD will be promoting its innovative products and services by exhibiting at the world’s largest 26th International sheet metal working technology exhibition - “EuroBLECH 2022”, from 25th – 28th October’2022 at the Hanover Fairgrounds, Hanover, Germany, and we are at 13 HALL, STALL NO. D184E

About the Exhibition:

“EuroBLECH” is specifically targeted to the sheet metal working industry, featuring a global audience of visitors ready to invest and demonstrating a clear focus on technological excellence. In the current environment of volatile markets, it is thus the platform for international manufacturers and suppliers to the sheet metal working industry.

As a vertical trade show, ”Euroblech” covers the entire sheet metal working technology chain and offers the industry sector a unique marketplace for knowledge transfer, individual manufacturing solutions and worldwide business contacts.

This world’s largest sheet metal working technology exhibition which attracts top industry professionals from all over the world. It targets sheet metal working specialists at all management levels in small and medium-sized companies as well as large enterprises.

“EuroBLECH 2022" will be occupying halls 11, 12, 13, 14, 15, 16, 17, 26 and 27 at the Hanover Exhibition Grounds in Germany.

The new hall 26 will host exhibitors of joining technology, as well as surface and tool technology.

We, GUANGZHOU BLUE SKY MACHINE CO LTD offer a range of Sheet Metal Equipment and Production Lines. Cut to length line, Slitting line, Tube Mill and Roll Forming Machine with latest technology and world-class quality standard.

GUANGZHOU BLUE SKY MACHINE CO LTD have supplied these Cut to Length Line, Slitting Line, Tube Mill and Roll Forming Machine to over 60 countries.

We have built our FULL TIME SALES & SERVICE TEAM both in CHINA & INDIA. Even under covid situation, our commissioning & service team already successfully commissioned about 139 nos. roll forming machines, 63 nos. cut to length lines, 78nos.slitting line, 126 tube mills in many countries in the world. Our customers are satisfied with our quality and service.

We cordially invite you to experience the World Class Innovative Technology for Slitting/ Cut to Length/Tube Mills and Roll Forming at 13 HALL, STALL NO. D184E.

GUANGZHOU BLUE SKY MACHINE CO LTD team is looking forward to welcome all visitors to our Stall.

See you soon…!!!

IMTEX FORMING & TOOLTECH 2022 Exhibition in Bangalore, Karnataka (INDIA) from June 16th-21st June is going on.

Welcome to our Hall NO – 04, STALL NO. – C135.

We, Blue Sky Machine, as a professional manufacturer of roll forming machines, cut to length lines, slitting lines, and tube mills. Welcome to visit us.